Terminals are key component of wire harnesses. They have various types with diverse functions. In order to improve the quality of wire harnesses and ensure the stable operation of electrical systems, it is necessary to understand the characteristics and selection of different terminal. In the following sections, with the aim to provide you with practical recommendations and a comprehensive perspective for your wire harness applications, we will study the various types of terminals.

Ring Terminals

Crimping or welding techniques must be employed to achieve the connection of ring terminals to wires. These terminals are typically compatible with specific stud sizes and wire gauges. They feature a kind of hollow circular conductive material which allows the passage of a screw or stud.

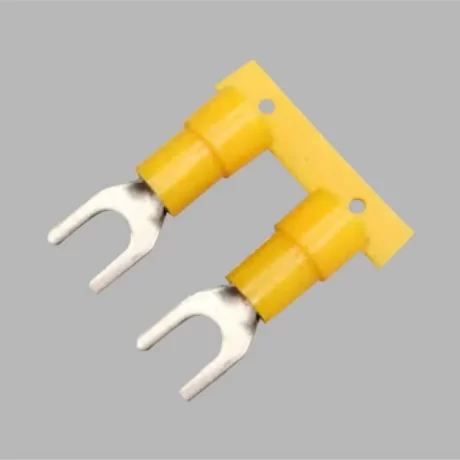

Fork Terminals

Allowing for easy installation or removal from screws, fork terminals derive their name from their shape. These terminals are available in multiple sizes and insulation classes. They offer unique applications in installation sites with limited space.

Hook Terminals

For many projects, hook terminals may provide a more straightforward and durable and installation method. Insulated or non-insulated hook terminals can be obtained. Hook terminals are shaped like hooks, making them highly convenient for loading and unloading.

Quick Disconnect Terminals

Available in insulated or non-insulated versions, quick disconnect terminals serve as a stable source for wire connections. With this type of terminal, systems with current can be connected and disconnected. Quick disconnect terminals are commonly used in the automotive and consumer goods industries to achieve reliable connections between two wires.

Bullet Terminals

This type of terminal is resistant to rust, protecting circuits from dirt, dust, and other contaminants. Additionally, bullet terminals include male and female ends that form a firm connection. They also allow for the disconnection of wires. Bullet terminals, or bullet connectors, enable reliable and secure connections repeatedly.

Butt Terminals

Against abrasion, cutting, butt terminals prevent moisture from entering the connected junctions. At one time, they can help terminate single or multiple wires. As they can be paired, the wiring range can be extended by butt connectors.

Flag Terminals

Flag terminals, also known as flag connectors, help create secure and convenient connections. Where quick disconnects may be overly critical, these terminals work extremely well in narrow installation spaces. In both insulated and non-insulated forms, they provide a simple connection-disconnect mechanism therefore.

Open-Type Terminals

Serving as key components to enhance the quality of wiring harnesses and ensure the stable operation of electrical systems, open-type terminals demonstrate their superiority in various wiring harness applications. Their characteristics include a simple structure, convenient operation, and good electrical conductivity. Open-type terminals play a significant role in electrical systems due to their unique design and performance as a common type of wiring harness connector.

Closed-Type Terminals

During long-term use, closed-type terminals can maintain excellent connection effects, thanks to their excellent electrical performance and durability. Compared with open-type terminals, they have a more compact design and exhibit stable performance in vibrating environments, with strong durability. As another type of wiring harness connector, closed-type terminals also have their unique features.

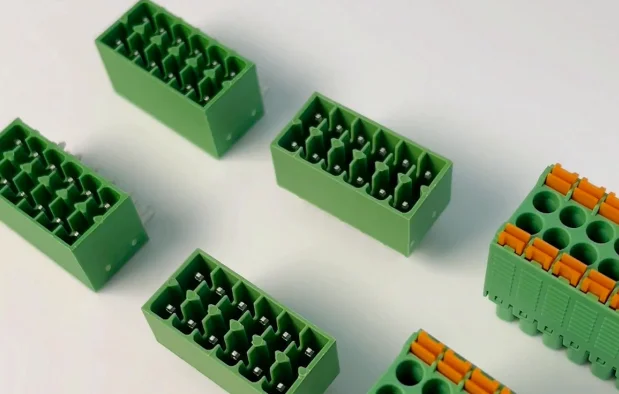

Plug Terminals

Plug terminals are widely used in electrical, electronic, communication, and other fields. They are characterized by easy installation, allowing wire connections without tools, and secure fastening that does not loosen even when machines or equipment are vibrated. Plug terminals are commonly used wire connectors, typically divided into panel plug terminals and rail plug terminals.

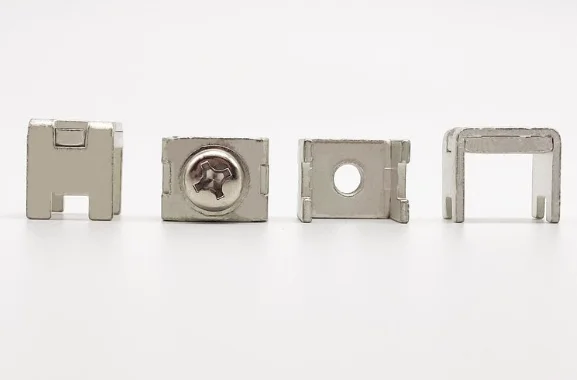

Screw Terminals

Screw terminals are mostly used in machinery and equipment, power facilities, and other fields. They are characterized by firm connections, low probability of wire loosening, simple structure, and convenient use. Screw terminals are commonly used connectors, typically used to connect wires or equipment.

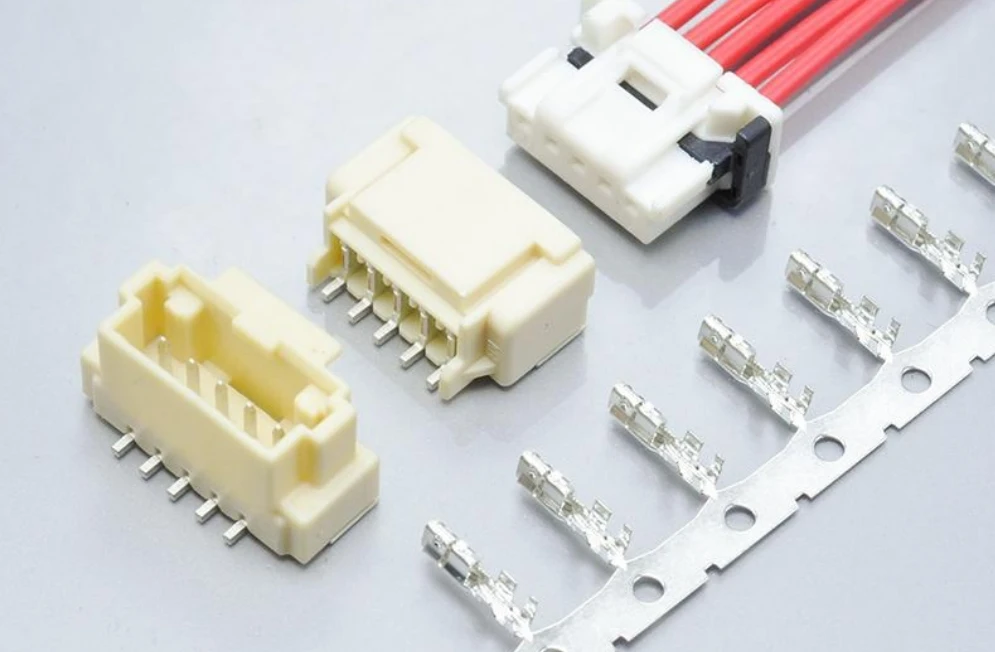

Crimp Terminals

They are widely used in electronics, electrical engineering, communications, and other fields. Crimp terminals are characterized by firm connections, high reliability, and long service life. Typically, wires are inserted into the terminals, and then the terminal’s connection ports are crimped through tools to tightly connect them with the wires. Crimp terminals are commonly used wiring terminals.

Spring Terminals

Spring terminals are widely used in electronics, communications, and other fields. This type of terminal features a simple structure, convenient use, and great convenience in installation and maintenance. Typically, wires are inserted into terminal holes, and the wires are secured to the terminals by springs inside the terminals. Spring terminals are a type of wiring terminal.

Cold Press Terminals

They are used in power facilities, machinery and equipment, and other fields. Cold press terminals are characterized by long service life, convenient installation, firm and reliable wiring. Their connection method mainly involves using special tools to cold-press the wires at both ends, forming an integrated structure between the terminals and the wires. Cold press terminals are commonly used wiring terminals.

Continue Reading

How to Analysis Terminal Material and Welding Process?

Electrical Terminal Materials: 4 Key Points (+How to Select?)

Connection Methods and Analysis of Terminals and Connectors(5 Necessary Steps)

How many types of connector and terminal insulation materials(3 major categories)

What factors determine the cost of electrical terminals and connectors? (10 Key Factors)

What Certifications Do Terminals and Connectors Need? (6 Common Types)