Your Trusted Electrical

Terminals and Connectors

Partner

Original Electrical Terminals Connectors OEM & ODM Service Provider

New Electrical Terminal and Connector Products

Insulation Types

- Insulated Terminals

- Uninsulated Terminals

- Pre Insulate Terminals

- PVC Insulated

- Heat Shrink Insulated

Termination Types

Connector Gender

Contact Material

-

$10Original price was: $10.$9Current price is: $9. -

$10Original price was: $10.$9Current price is: $9.

Our Electrical Terminal and Connector Services

Terminal Mold Development

Terminal Mold Development

Terminal OEM & ODM Service

Terminal OEM & ODM Service

Fast Certification

Fast Certification

Customized Packaging

Customized Packaging

Industries We Serve

LED / Lighting

Sustainability, innovative connecting parts that meet the ever-changing Requirement update in the lighting industry.

Wire industry

High-quality, cost-effective terminals and connectors that provide the best possible connection and ensure continuity.

Automotive

Automobile needs a complex network of electrical terminals and connectors to protect circuits. Our custom solutions and pro-duction lines ensure high quality terminal and connector parts.

Appliance

Terminals are widely used in household appliances. lt must meet the challenges of high vibration, high temperature, and heavy use.

Medical Electronics

Our medical terminals are of high precision, guaranteed safety and reliability, and designed in accordance with medical industry standards.

Battery / Solar Energy

In batteries and energy devices, electrical terminals are essential for ensuring power transfer efficiency and peripheral control. Our terminals are made of high-quality metal materials and are lead-free.

Consumer Devices

Consumer electronics products are changing very fast, which requires customized electrical terminals to meet the their requirements. We have rich experience in the field of consumer electronics and can meet your needs.

Telecom

Telecom equipment consists of transmission equipment, relay stations, branch stations and data terminals. The stability of data transmission is very important, and electrical terminals play animportant role in the connection.

Military

Terminals in the military industry need to work in harsh climates. maintain reliability, and comply with relevant standards.

About KingTerminals

13 + Years

Years of Professional Experience

1500 +

Types of Terminals

15002

Square Meters of Factory Area

68 +

Patented Technology

Electrical Terminal and Connector FAQS

What do electrical terminals and connectors refer to?

Electrical terminals and connectors are the main components of electrical systems. However, they have differences.

Electrical terminals are elements that are applied to link the end of a wire to an electrical appliance or another wire, which offers a secure point of attachment. They are specifically built to fit over or across a stud, bolt, or screw to make sure a firm mechanical and electrical connection can be achieved.

Functioning as devices employed to connect two or more wires or cables together, electrical connectors help promote the transmission of electrical signals or power between elements. Continuity, insulation, and protection against environmental factors can be ensured. Connectors can be temporarily or permanently functioned, which is decided by the application. And they are designed in different kinds, which include male or female plugs, push-in, and crimp connectors.

How many types of electrical terminals?

Multiple kinds of electrical terminals serve various purposes, which depend on the application:

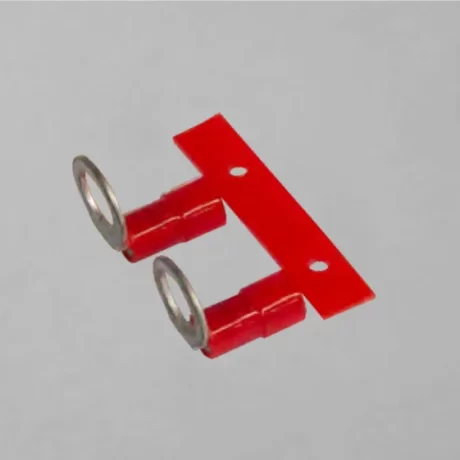

- Ring Terminal: This type of terminal contains a connector that has a ring shape. The connector is placed over a stud or bolt and then fastened with a nut or screw. It is widely applied in automotive and industrial settings to achieve the connections of secure grounding.

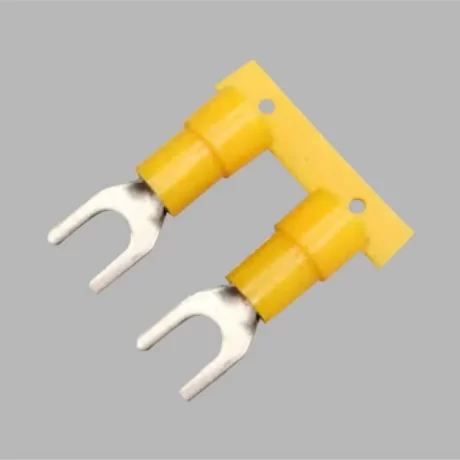

- Spade Terminal (Fork Terminal): These terminals are shaped like a fork, enabling the quick connection and disconnection. They are applied in cases where a secure connection is required but frequent disconnection may be need as well.

- Butt Connector: Two wires are connected end-to-end by these terminals, which ensures continuity and signal transfer. These terminals are widely applied in auto and marine wiring.

- Quick Disconnect Terminal: This type of terminal is crafted explicitly for swift and easy connections. It can be male or female, which allows users to achieve the rapid joint or separation of two electrical wires.

- Bullet Terminal: This terminal is a male connector shaped like a bullet that fits into a corresponding female terminal, which provides a secure connection that can be disconnected if required.

- Pin Terminal: This is applied to link a single wire to another connector, especially in narrow spaces where other kinds of terminals may not fit.

Can electrical terminal connectors be able to be reused?

In most circumstances, electrical terminal connectors are not built to be used again, especially those that have been crimped or soldered onto wires. Permanent connections can be achieved once the connectors are crimpled or soldered. The reuse of the terminal can compromise the integrity of the connection, which potentially results in electrical malfunction or poor conductivity. However, specific terminal connectors like quick disconnect terminals, push-in connectors, and screw-type terminals are built for the achievement of connections and disconnections. They can be used in a safe way, given that inspections of wear or damage are conducted before the application.

It is crucial to evaluate the status of the terminal connector before using it again. It is advisable to replace the terminal to make sure a reliable and secure connection can be achieved in case of any signs of wear, corrosion, or physical damage.

How to install for electrical terminals and connectors?

The setup process of electrical terminals and connectors remains straightforward. However, a secure connection should be carefully considered:

- Stripping Wire: A wire stripper should be applied for the removal of a small part of insulation from the wire, which exposes the metal conductor.

- Inserting Wire: The stripped end of the wire into the terminal connector should be inserted, ensuring the full seating of the conductor within the terminal.

- Crimping Terminal: A crimping tool should be applied to compress the terminal surrounding the wire. A secure connection should be ensured since a poor crimp can lead to a weak electrical link or wire pullout.

- Inspecting Connection: The terminal should be gently tugged to ensure the secure attachment after the wire is crimped. If needed, heat-shrink tubing should be used to offer extra insulation.

What are the purposes of electrical terminal connectors?

Electrical terminal connectors are applied to join wires and components contained in an electrical system. The secure electrical connections can be ensured, and the insulation helps avoid issues like short circuits, electrical shocks, or fire risks. Universal applications of terminal connectors contain:

- Auto Wiring: Terminal connectors are applied for the connection of battery terminals, lighting systems, and sensors in cars.

- Home Appliances: The connectors can be found in wire devices like washing machines, refrigerators, and HVAC systems.

- Electrical Panels: These connectors are helpful for organizing and securing wiring inside electrical panels to keep the integrity of the electrical device.

- Industrial Devices: Factories and manufacturing machinery commonly require these connectors to endure high-voltage electricity and ensure secure connections when they are in heavy use.

How to selecor correct terminal connectors for an application?

The selection of the matched terminal connector for your electrical project is decided by the following factors:

- Wire Type: The gauge and kind of wire you work with should be considered. Connectors rated for specific wire sizes should be selected, and an incompatible terminal used can result in a poor connection or damage to the wire.

- Environment: Terminals with appropriate insulation should be chosen for the condition. Take an example, heat-shrink terminals can be applied in settings where heat, moisture, or chemicals may be encountered.

- Voltage & Current Rating: The terminal connector that is rated for the voltage and current carried by the system must be confirmed to avoid issues such as overheating or failure.

- Connection Type: A decision of a need of permanent connection (such as a crimp or soldered terminal) should be made. Also, you need to choose if a quick disconnection is needed for frequent replacement or maintenance.

- Material: Terminals made from corrosion-resistant materials like tinned copper should be applied for highly corrosive conditions like marine settings.

Are there any advantages of applying electrical terminal connectors?

Multiple benefits are shown below for the use of electrical terminal connectors in your electrical projects:

- Secure Connection: A reliable way is provided by terminals for the connection of wires, which ensures the secure connection or disconnection because of the vibration, pulling, or other environmental conditions.

- Insulation: Featuring insulated coverings, lots of terminal connectors give protections against moisture, dust, and other contaminants that lead to corrosion or other issues like electrical shorts.

- Easy Use: The quick connection and disconnection to the wires can be easily achieved by terminal connectors. This plays an essential role in auto, electrical devices, and industrial systems that require maintenance or troubleshooting.

- Less Occurrence of Short Circuit: Terminal connectors are helpful for the decrease of the risk of short circuits and electrical failure through the secure connection of wires and the prevention of the contact with other conductive surfaces.

What are the materials used to manufacture electrical terminal connectors?

Electrical terminal connectors are generally designed from highly conductive materials to confirm that efficient power transfer can be achieved. Some widespread-used materials cover:

- Copper: Copper is welcomed for its great conductivity, and it is the most universally applied material for electrical terminals. It usually has coatings with a protective layer of tin to avoid corrosion.

- Brass: Brass terminals have conductivity as well and provide great resistance to corrosion. In typically cases, they have wide applications in automotive and marine settings.

- Tinned Copper: Terminals made from tinned copper feature an extra layer of tin over the copper, which offers additional protection from corrosion, particularly in moisturized conditions such as marine settings.

- Aluminum: Aluminum terminals feature lightweight, and applied in certain high-voltage power transfer applications. However, they are less commonly used than copper because of lower conductivity.

What common issues are encountered when using electrical terminals and connectors?

Some commonly encountered issues caused by improper setups or environmental conditions can arise though electrical terminal connectors have strong reliability. The issues contain:

- Loose Connection: The connection may loosen over time If a terminal is not in proper crimping or soldering, which may lead to electrical faults or intermittent problems.

- Corrosion: Corrosion may happen on metal terminals in conditions with moisture or chemical substances, which causes poor electrical conductivity. Insulated or tinned terminals used are helpful for mitigating this issue.

- Overheating: Issues like overheating may occur if an incompatible terminal with the voltage or current of the system is used. this may further lead to melted insulation ot the damage to the wire.

- Poor Crimping: A weak electrical connection or the pullout of the terminal may be caused by a poor crimp, resulting in electrical faults. The matched crimping tools should always be applied for the terminal in use.

How can corrosion be prevented in electrical terminals and connectors?

Poor connections and electrical faults may be caused by corrosion, particularly in extreme conditions like marine or outdoor applications. The way to avoid corrosion in electrical terminals is listed below:

- Apply Tinned Terminal: Tinned copper or other materials that are resistant to corrosion are helpful for the prevention of oxidation in highly wet areas.

- Use Dielectric Grease: A thin layer of dielectric grease should be applied on the terminal, generating a moisture barrier that avoids corrosion, particularly in auto and marine devices.

- Select Terminals with Insulation: Insulated terminals like heat shrink terminals, achieve the addition of an additional layer of protection from environmental conditions that can lead to corrosion.

- Regular Inspect and Clean: Periodical Inspection of terminals should be conducted in high-moisture or coastal areas in particular. Terminals should be cleaned if any oxidation is visible and corroded terminals should be removed as required.

How should wires be organized for the use of electrical terminal connectors?

Terminal connectors are helpful for the organization of wires by grouping them into a structured arrangement, which plays a crucial role in control panels, auto wiring harnesses, and electrical systems. The maintenance of the organization is shown below:

- Apply Terminal Blocks: Terminal blocks are helpful for the connection of several wires in an organized and structured manner, which enables easy identification and problem-solving.

- Label Wires & Terminals: Each wire and its corresponding terminal should be labelled to ensure the right connections and simplified troubleshooting.

- Apply Cable Ties or Wire Looms: Cable ties or wire looms should be used for the organization of wires so as to avoid tangling and allow protection against abrasion.

What are the practical applications of electrical terminals and connectors in auto settings?

Electrical terminals and connectors are useful for ensuring secure and vibration-resistance connections between the wiring and components of vehicles in auto settings. The widespread applications include:

- Battery Connections: The connection of the car’s battery with the electrical system can be achieved by the use of ring terminals, which ensures a powerful and corrosion-resistant connection.

- Lighting Devices: Easy removal for maintenance can be achieved by the typical applications of bullet terminals in headlights, taillights, and other car lighting systems.

- Engine Sensors & Components: Reliable connections between sensors, relays, and the electrical control system of vehicles can be ensured, even in high-vibration and high-temperature conditions.

How can issues be troubleshot with electrical terminals and connectors?

Regarding the troubleshooting of electrical terminals and connectors, the steps below should be followed:

- Corrosion Check: Any signs of corrosion should be checked for terminals, moisture-prone conditions such as automotive or marine systems in particularly. Poor electrical conductivity and intermittent failures may be caused by corroded terminals.

- Loose Connections Inspection: The secure connection of all terminals should be ensured to prevent electrical faults, arcing, or intermittent problems.

- Test Continuity: A multimeter should be employed to inspect continuity across terminal connections. This ensures the free flow of electrical current through the terminals.

- Avoid Overheating or Melting: Any signs of overheating for the insulation and connectors should be checked. The issues contain melted plastic or discoloration, indicating an overload or poor connection.

How is the efficiency in wiring projects enhanced by electrical terminals and connectors?

Significant improvement of the efficiency and safety of wiring projects can be achieved by electrical terminals and connectors through:

- Simplify Connections: Swift and easy wiring of several components can be achieved by terminal connectors, which decreases the complication of the wiring layout.

- Reduce Downtime: The performance of maintenance and repairs can be easily achieved by quick disconnect terminals, which reduce the downtime of the system in industrial or auto conditions.

- Enhance Safety: Secure and insulated connections can be achieved by the proper installation of terminals and connectors, decreasing the hazard of electrical failures, overheating, and power shorts.

- Streamline Setup: A wide range of terminal kinds available achieves better efficiency for the wiring projects, which results in less time-consuming and labour costs.

Looking for Electrical Terminal and Connector Products for Your Projects?

Connect Our Team

Address: No.3, 168 Industrial Zone, Xincun Street, Tangxia Town, Dongguan City, Guangdong Province, China

Applications

- Wire Terminals

- LED Terminals

- Auto Terminals

- Battery Terminals

Services

Get Answers Now