What Are the Terminal Materials?

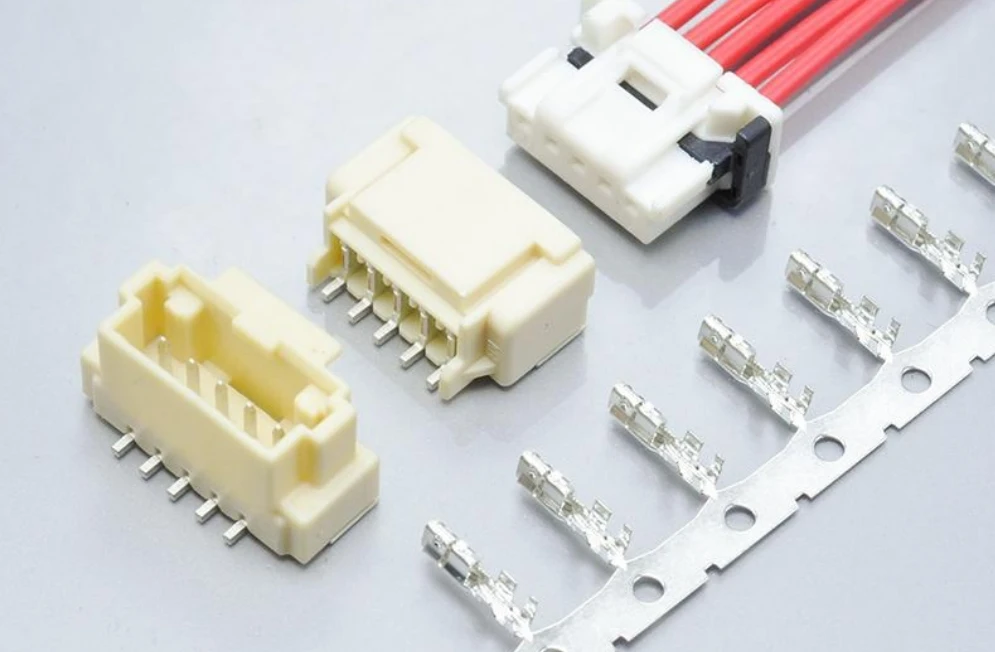

Terminals are the parts that connect the battery to external conductors. They are mainly used to deliver electrical signals or conduct electricity. A terminal typically, in electrical engineering, refers to a connection terminal, also known as a terminal block. According to material, they can be classified into iron, aluminum, pure copper, zinc-plated copper, silver-plated copper, etc. They come in various types, such as single-hole, double-hole, socket, and hook terminals. In the area of electrical connections, terminal blocks are key parts to guarantee circuits’ stable operation. While both ordinary terminal blocks and copper tube terminal blocks exhibit significant differences in multiple aspects and undertake the purpose of connecting wires.

Core Functions and Technical Standards of Terminals

- Environmental Adaptability:

When it comes to salt spray, its test indicates metal terminals exhibit 3-5 times the lifespan of iron terminals in corrosive conditions.

- Mechanical Strength:

When it comes to iron terminals, they can, through plating treatments, satisfy the load-bearing requirements of conventional connectors.

- Electrical Conductivity:

When it comes to metal terminals (i.e., copper alloys), they generate lower resistivity, so that they can be suitable for the scenarios of high-current transmission.

How Many Typical Application Scenarios of Metal Terminals?

- Marine Engineering

Titanium alloy terminals, an important terminal, are employed to resist seawater corrosion.

- Rail Transit

Nickel-based alloy terminals, popular in rail transit, are applied to resist temperature fluctuations and vibrations.

- High-Voltage Power Transmission

Silver-plated copper terminals, a common material in high-voltage power transmission, are employed for busbar linking in substations.

Terminals Made of Different Materials

Introduction to Copper Terminals

Copper terminals are widely used in electronic devices, because they are famous for its excellent corrosion resistance and high electrical conductivity and. Copper terminal connectors, being particularly common in high-end equipment, not only have a longer service life but also have good conductivity performance.

Stainless Steel Terminals

Stainless steel is a preferred choice in medical and industrial equipment, because it is celebrated for its high strength and corrosion resistance. Stainless steel terminal connectors can withstand harsh environments as they offer long service life.

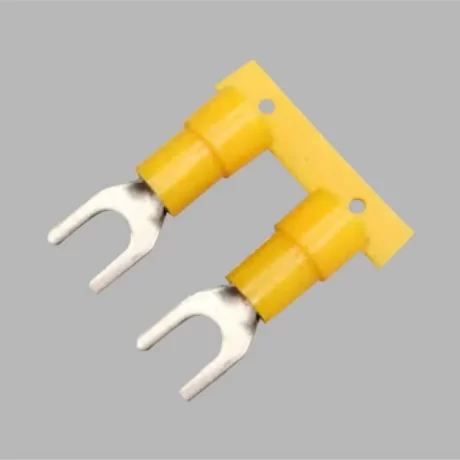

Iron Terminals

1.Temporary Power Supply: Detachable iron terminals facilitate quick installation.

2.Home Appliance Manufacturing: The fee is 40%-60% lower than metal terminals.

3.Power Distribution Systems: Galvanized iron terminals can be used in indoor dry environments.

Aluminum Terminals

Aluminum is suitable for applications requiring weight reduction. Aluminum terminal connectors possess decent electrical conductivity and are lightweight. Due to its lightweight properties, it is widely used in aerospace.

Zinc Terminals

Zinc terminal connectors is a more economical choice in certain scenarios because of its price advantage. Compared with copper, its conductivity and corrosion resistance are inferior. Zinc terminal connectors are typically used in applications with low-cost, such as household appliances.

Heat-Shrink Terminals

Thermoplastic terminal connectors, made from thermoplastic materials, offer excellent mechanical strength, corrosion resistance, insulation, and fire-retardant properties. They are widely applied in low-voltage power systems and building electrical installations.

Copper Terminals VS Other Terminals: What Are the Advantages?

Ordinary terminal blocks utilize more diverse materials compared to copper tube terminals. For instance, common choices include brass—often with lower copper content and added metals like zinc—or aluminum alloys, which are more cost-effective but exhibit differences in certain performance aspects. In contrast, copper tube terminals are predominantly fabricated from copper, with widely used high-purity oxygen-free copper (red copper). This material stands out for its exceptional electrical conductivity, thermal conductivity, and corrosion resistance.

Conductivity

Among ordinary terminals, aluminum alloy terminals exhibit a more significant conductivity gap compared to copper tube terminals due to the inherent properties of aluminum alloy. During high-current transmission, they may have substantial resistance, causing heat generation and potentially impacting equipment normal operation. Brass terminals, another type of ordinary terminals, offer acceptable conductivity but are slightly less effective than red copper. In contrast, copper tube terminals leverage copper’s excellent conductive properties to deliver outstanding electrical performance. Their low resistance greatly reduces power loss during current transmission, efficiently minimizing heat generation and ensuring efficient and stable power transmission, especially in high-current electrical connection scenarios.

Applicable Scenarios

Ordinary terminals are more suitable for general electrical equipment with relatively favorable usage environments and low current requirements, such as internal connections of small household appliances and daily lighting circuits. Ordinary terminals can fully perform their functions, they can excel in these scenarios, and they have prominent advantages regarding to the cost. In contrast, copper tube terminals are frequently applied in power grids and large industrial equipment. These fields have extremely high demands for power transmission stability and need long-term stable electrical connections. Copper tube terminals excel in these areas owing to their excellent conductivity and corrosion resistance, and can reliably fulfill such requirements.

Mechanical Strength

Ordinary terminals can achieve elevated mechanical resilience and sustain stable connections even in such environments, that is the environment is prone to significant external tension or vibration when they undergo reinforcing treatments and are fabricated from suitable materials. This is particularly evident in certain specially processed variants, such as high-strength brass terminals. In contrast, copper tube terminals possess ability to create a secure and intimate connection and closely conform to wires during installation due to their malleable nature. Compared to these reinforced standard terminals, they may exhibit marginally lower mechanical durability.

How to Select Suitable Terminals for Your Project

- Conductive Requirements: For current transmission exceeding 100A, metal terminals are preferred due to their excellent conductivity.

- Budget Constraints: Iron terminals cost only one-third of metal terminals per unit.

- Maintenance Cycle: One should opt for maintenance-free metal terminals in corrosive environments,

- Material: Copper Terminals: High conductivity and corrosion resistance give them higher value, suitable for high-performance applications with strict requirements. Plastic Terminals: Lower cost results in relatively lower value, making them ideal for ordinary applications with moderate performance needs.

- Model and Specification: Terminal models and specifications directly affect their value. Larger-sized and high-performance terminal connectors generally have higher market value due to their technical complexity.

- Service Life: The service life of terminal connectors is a key factor in evaluating their value. High-quality connectors offer longer service life, thus fetching higher value during recycling.

To ensure the safe and stable operation of electrical systems in installation and maintenance, it requires precise selection of appropriate terminal blocks, which hinges on being aware of their differences. If we understand factors like service life, specification, model, material, we will better select and use terminal connectors. These efforts also maximize their recycling value. The material and value of terminal connectors are indeed influenced by multiple factors, including those mentioned above.

Continue Reading

How to Analysis Terminal Material and Welding Process?

How Many Types of Electrical Terminals and Connector?(Guide for 14 Types)

How to Select Copper Terminals and Connectors (12 useful Tips)

How many types of connector and terminal insulation materials(3 major categories)

What factors determine the cost of electrical terminals and connectors? (10 Key Factors)

What Certifications Do Terminals and Connectors Need? (6 Common Types)

Connector VS Plug-and-Socket Connector VS Terminal Block, What are they different?