Conceptual differences among “connector”, “plug-and-socket connector” and “terminal block”

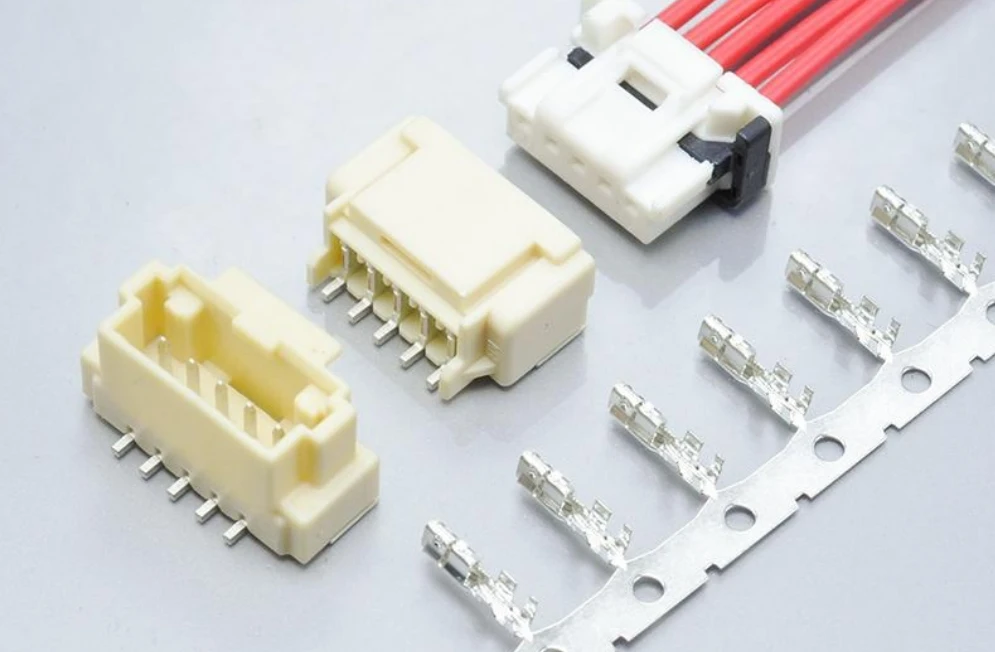

1. The connector is a broad category, commonly referred to as the “plug-and-socket connector” in China, also known as plug and socket. It is a component frequently used by electronic engineers, typically referring to electrical connectors that connect two electronic products to transmit current or signals.

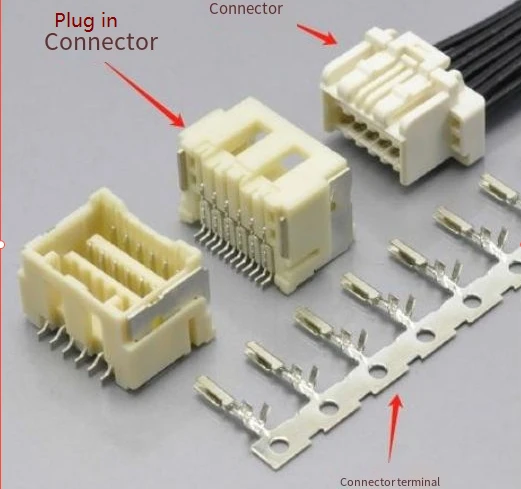

2. The plug-and-socket connector is a positioning joint for connecting electronic circuits, consisting of two parts – plug and socket – which are generally fully separable. Therefore, plug-and-socket connectors can also be called connectors.

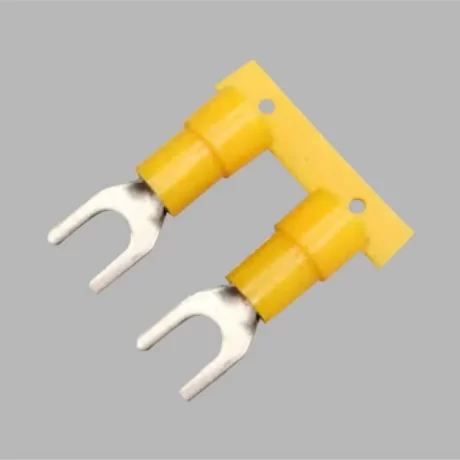

3. The terminal block is an accessory product used to achieve electrical connections, designed for convenient wire connections. It essentially consists of a metal strip enclosed in insulating plastic with holes at both ends for inserting wires. Terminal blocks can be categorized into plug-in terminal blocks and European-style terminal blocks.

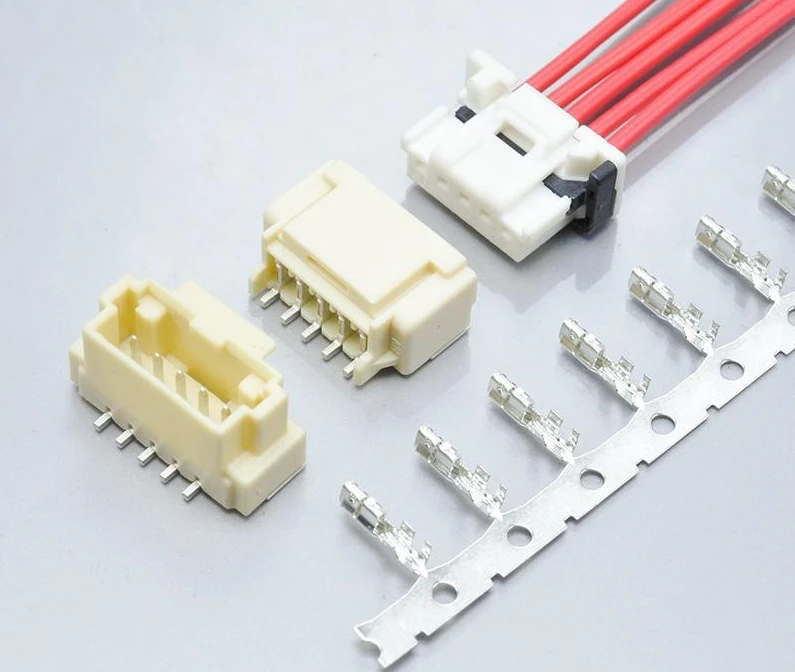

For a very simple and rough distinction, refer to the following diagram (only applicable to connectors produced by KingTerminals):

Rough distinction

According to our engineers: Connectors and plug-and-socket connectors are essentially the same concept. The standard term is “connector”, while “plug-and-socket connector” is the common term in China. They bridge two conductors in a circuit, enabling current or signals to flow from one conductor to another. Widely used in various electrical circuits, they serve to connect or disconnect current or signals. This type of connection allows for easy plugging and unplugging without tools to establish or break the circuit, whereas terminal blocks generally require tools such as screwdrivers or crimping pliers to connect two points. Representative products include terminal blocks, lugs, and European-style terminals.

Practical application differences among “connector”, “plug-and-socket connector” and “terminal block”

1. Electrical connectors, abbreviated as connectors and also called plug-and-socket connectors, are a specialized segment of electronic components primarily used for inter-circuit connections. In modern electronic production, connector applications are ubiquitous, making their usage extremely widespread across various industries indirectly. For example, our KingTerminals series features a 2.0 mm pitch, with strengths in wear resistance, vibration resistance, high-efficiency transmission, and compact design. It is suitable for applications in new energy vehicles, consumer electronics, smart home systems, and more.

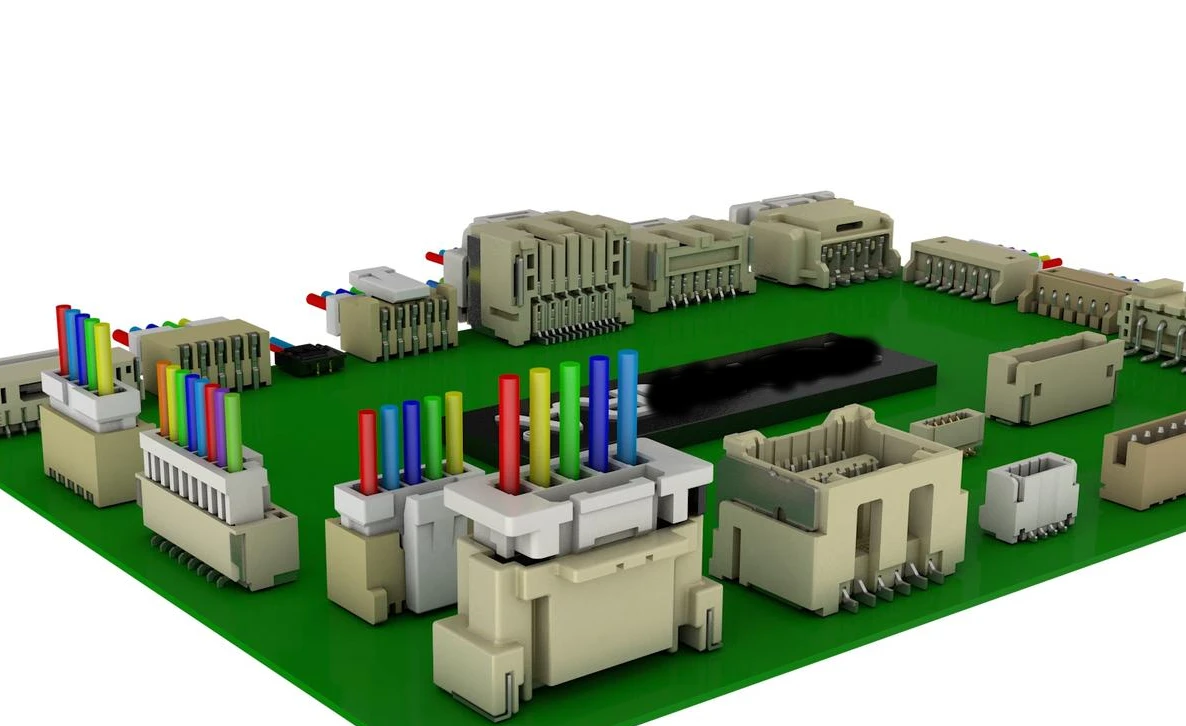

The forms and structures of connectors vary widely, with different types designed for specific applications, frequencies, power requirements, and environmental conditions. For instance, connectors used for stadium lighting, hard disk drives, and rocket ignition systems differ significantly. However, regardless of the type, connectors must ensure a smooth, continuous, and reliable flow of electric current. In a broad sense, connectors are not limited to connecting electric current only. Today, with the rapid development of optoelectronic technology, in optical fiber systems where light serves as the carrier for signal transmission and glass and plastic replace conventional wires in circuits, connectors are also used in optical signal pathways, fulfilling the same role as electrical circuit connectors.

2. The usage scope and variety of terminal blocks are expanding. Currently, besides PCB terminals, the most widely used types include hardware terminals, nut terminals, spring terminals, etc. In the power industry, there are specialized terminal blocks and terminal boxes filled with terminal blocks of various types, such as single-layer, double-layer, current, and voltage terminals.

In general, the electronic components “connector”, “plug-and-socket connector” and “terminal block” are different application manifestations of the same concept, colloquially referred to by various names based on different application industries, products, and positions.

Continue Reading

How to Analysis Terminal Material and Welding Process?

How Many Types of Electrical Terminals and Connector?(Guide for 14 Types)

Connection Methods and Analysis of Terminals and Connectors(5 Necessary Steps)

Electrical Terminal Materials: 4 Key Points (+How to Select?)

What factors determine the cost of electrical terminals and connectors? (10 Key Factors)