Operation and Safety of Terminal Machines

To ensure personal safety and the normal operation of the equipment, a series of safety regulations must be followed during operation. Whether the operation of the terminal machine complies with standards directly affects the quality and safety of the connection as a key device for wire harness connection.

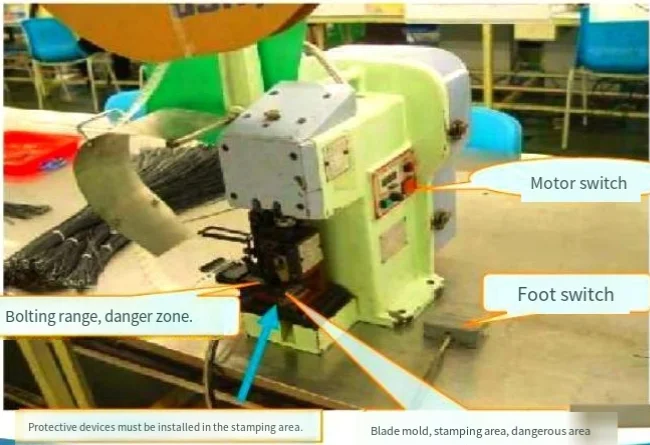

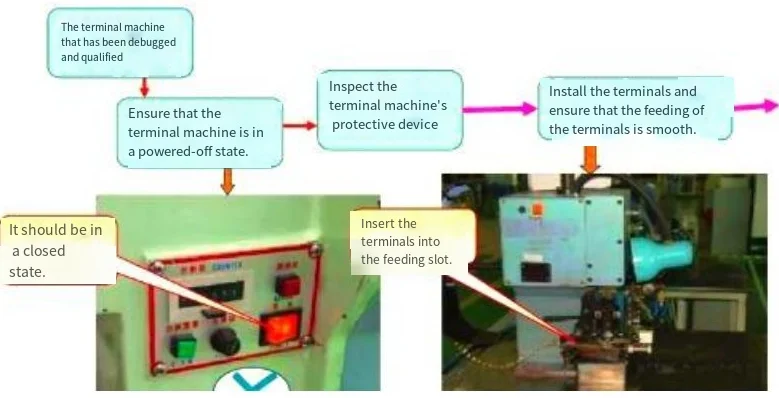

Preparation Before Startup

To ensure personal safety during operation, one needs to wear appropriate work clothes and protective gear as the final step. Additionally, carefully read the operation manual to familiarize yourself with the equipment’s performance and key operating points. By removing any obstacles that may affect the operation, it can ensure the safety of the equipment and the environment first. If any abnormalities are found, one needs to promptly carry out repairs or replacements to ensure all components are intact. In addition, one needs to inspect all components. These are the series of preparatory work that must be carried out before operating the terminal machine.

Powering on and Testing the Machine

Testing the machine by powering it on is the next step after completing the above preparatory work. Closely monitoring the equipment’s startup status and ensuring stable power supply are necessary at this stage. The relevant components should be inspected, and the operation should be stopped immediately if any abnormalities are detected. Laying a foundation for subsequent operations, the stability of the equipment’s performance can be further confirmed through testing.

Crimping Technology and Standards

A crucial link is the crimping of core wires in the power system. The safe operation of the entire system is directly affected, and the smoothness of the circuit is also related by it. Therefore, it is important to understand and master the correct crimping methods.

Mastering Correct Crimping Techniques

The safe operation of the system and the smoothness of the circuit can be ensured by reasonable crimping techniques in the power system. For ensuring the quality of the wiring, these techniques are of great significance.

Controlling the Precision of Stripping and Wire Placement

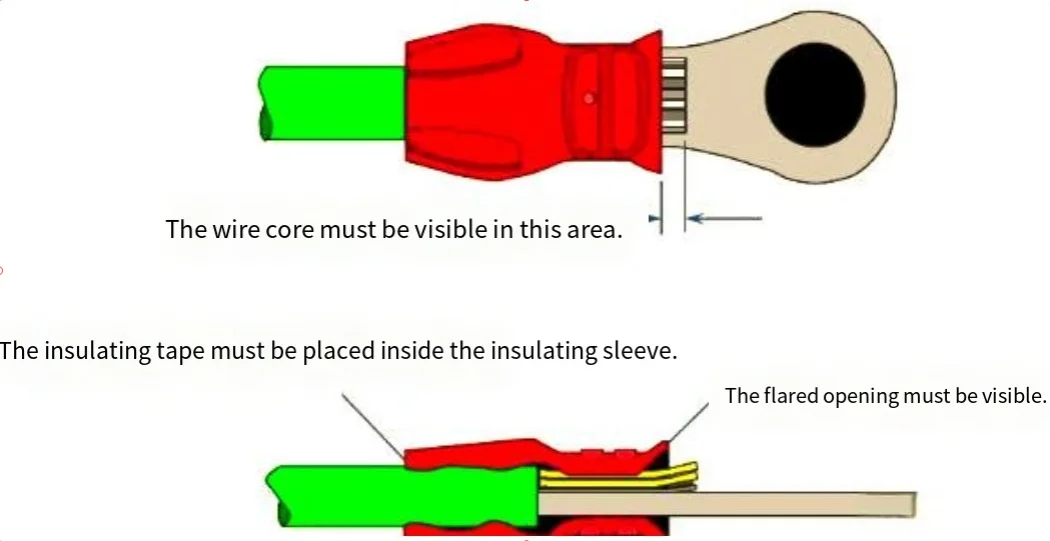

Of utmost importance is precise control of the stripping length and wire placement position during the core wire crimping process. Deviations during crimping may be led by inaccurate wire placement, while crimping quality will be affected by stripping lengths that are too short or too long. To ensure the smooth progress of the crimping work, it is essential to strictly control the precision of stripping and wire placement therefore.

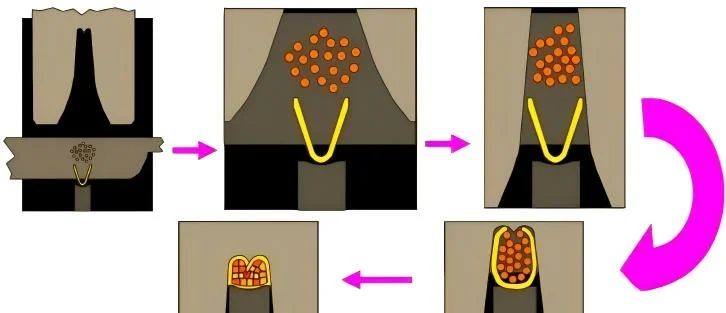

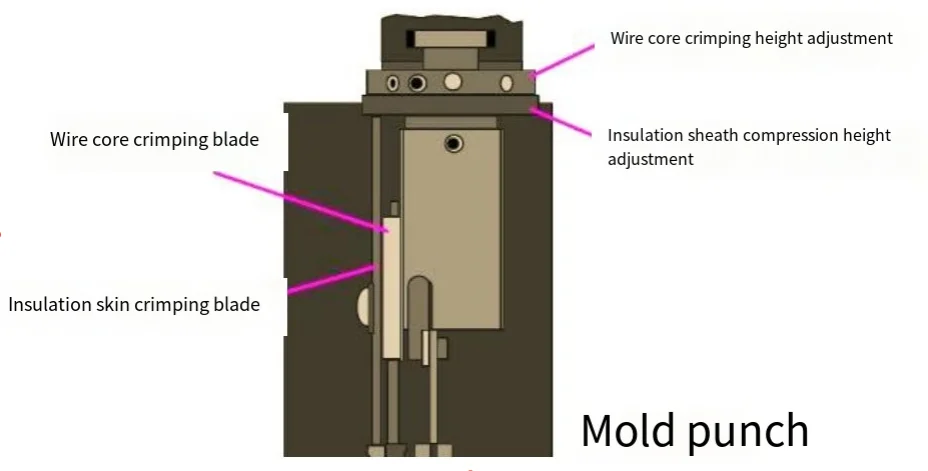

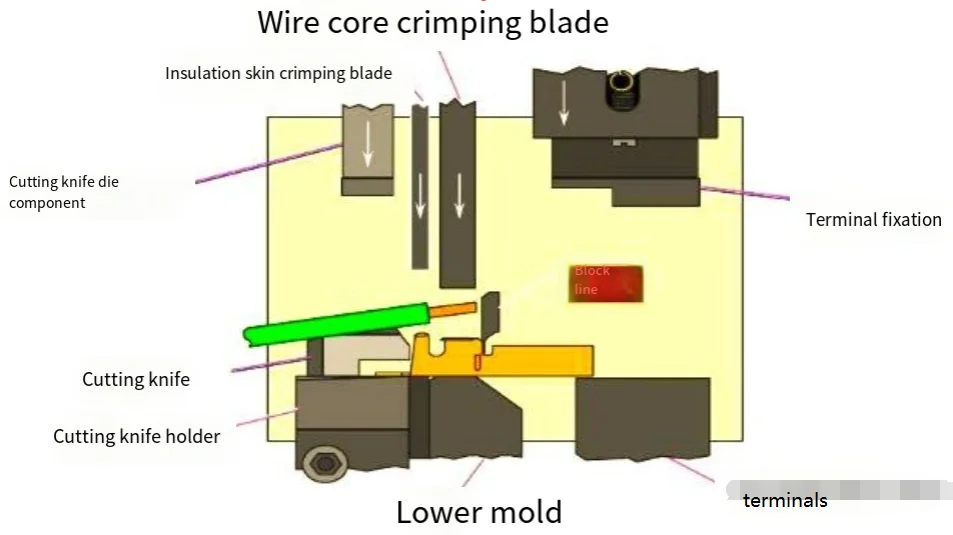

Fine Adjustment of Core Wire and Insulation Skin Crimping

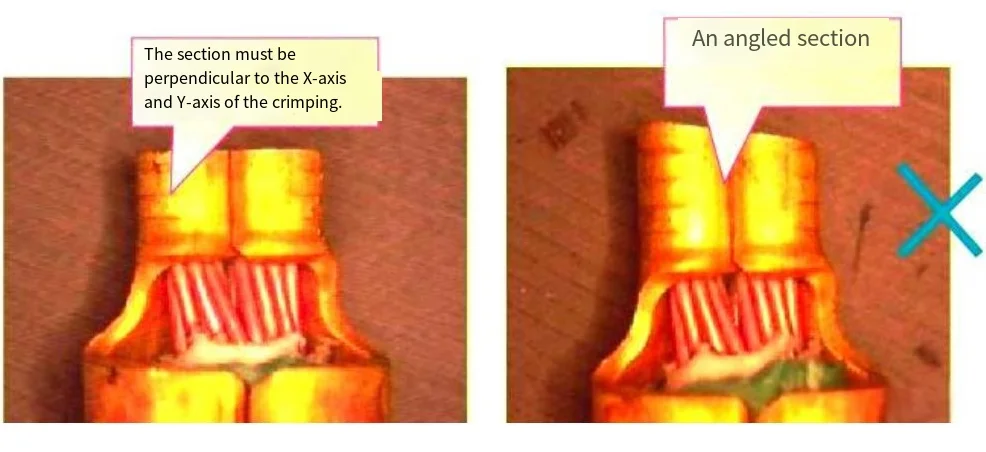

It is important not only to make fine adjustments to the crimping of the core wire and insulation skin but also to control the precision of wire placement and stripping during the core wire crimping process. This is because the force and crimping depth applied to the insulation skin and the core wire during crimping directly affect the final quality. Therefore, operators must flexibly adjust parameters and crimping tools based on actual conditions to guarantee that the insulation skin and core wire are properly and evenly crimped.

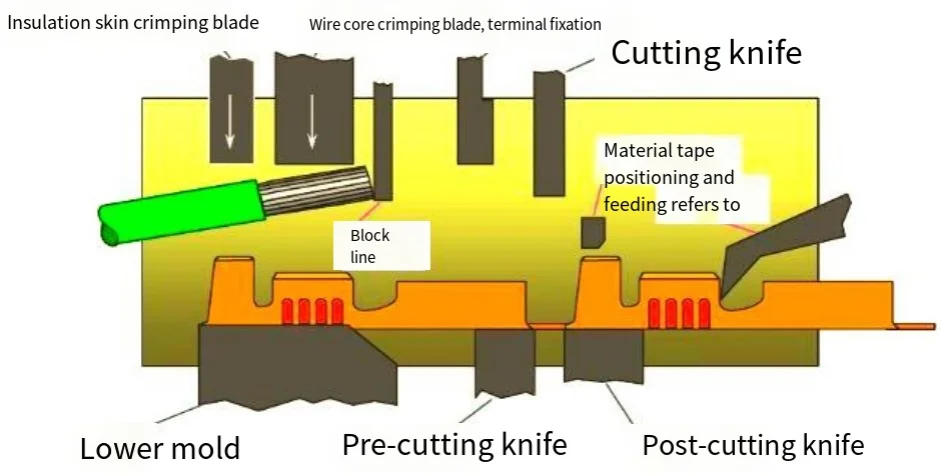

Precise Wire Placement and Post-Feeding Techniques

The selection of wire placement is of great significance during the process of core wire crimping. Feeding techniques and precise wire placement directly determine the crimping quality. This process guarantee that the insulation skin and core wire are crimped evenly with high quality. Therefore, the wire placement must be carefully adjusted and post-feeding techniques must be skillfully applied by operators to ensure uniform and high-quality crimping of the core wire and insulation skin.

Side Feeding Techniques

The proficiency in side feeding techniques is indispensable during core wire crimping, as it directly influences the uniformity, consistency, and overall quality of the crimp between the core wire and insulation skin. Operators must master these techniques to ensure precise and high-quality results.

Terminal Slice Analysis

Appearance Standards and Measurement

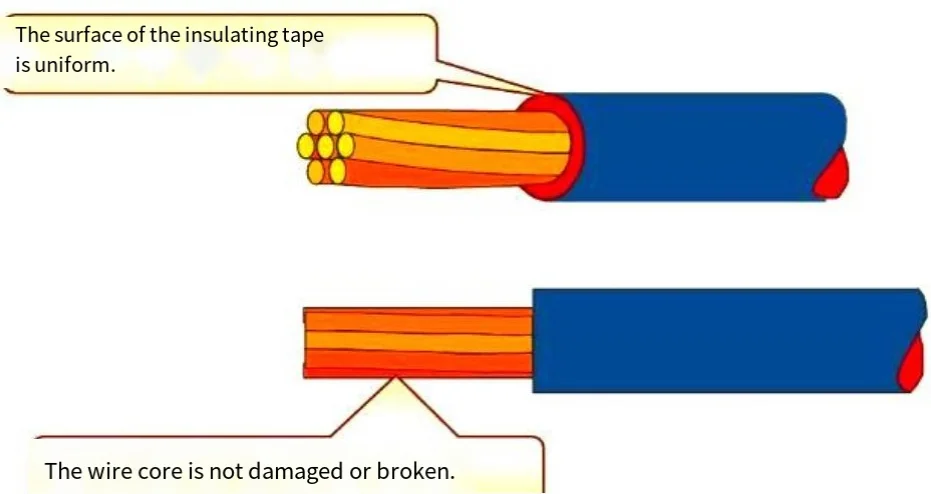

Ensuring circuit safety in core wire crimping requires strict adherence to stripping appearance standards and measurement methods, as a well-executed stripping appearance directly influences both crimping quality and overall circuit safety.

Failure Mode and Effects Analysis

To pay close attention to the failure modes of stripping appearance and their potential impacts and conduct in-depth analysis is essential during the core wire crimping process. We can more accurately grasp the standards for stripping appearance through systematic research on these failure modes and their effects. These efforts will ensure crimping quality and circuit safety.

Any damage or cutting of the core wire will directly lead to a decrease in its electrical conductivity during the core wire crimping process. This will, at the same time, also increase safety hazards during the operation of the circuit due to the impairment of the core wire’s mechanical strength. Therefore, in order to guarantee the safety and stability of the circuit, we need to ensure the integrity of the core wire and its electrical conductivity by paying close attention to the quality of the stripping appearance.

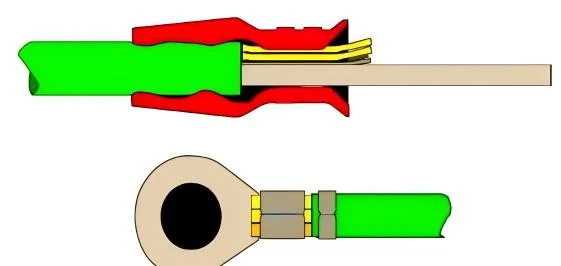

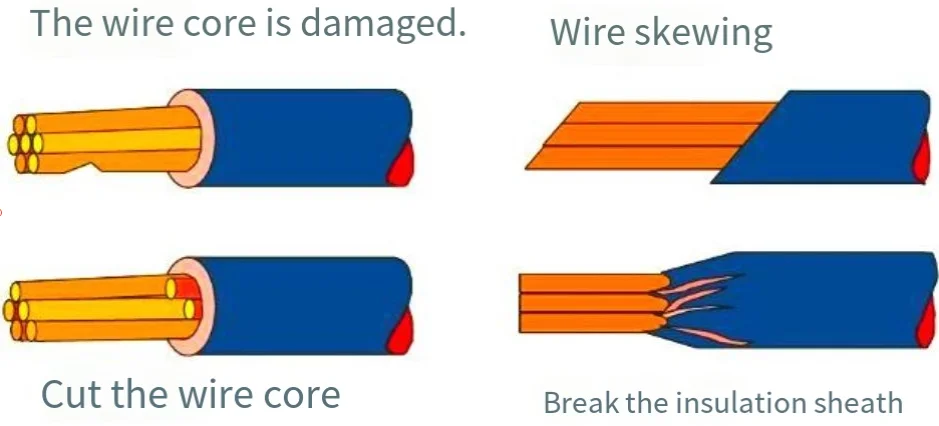

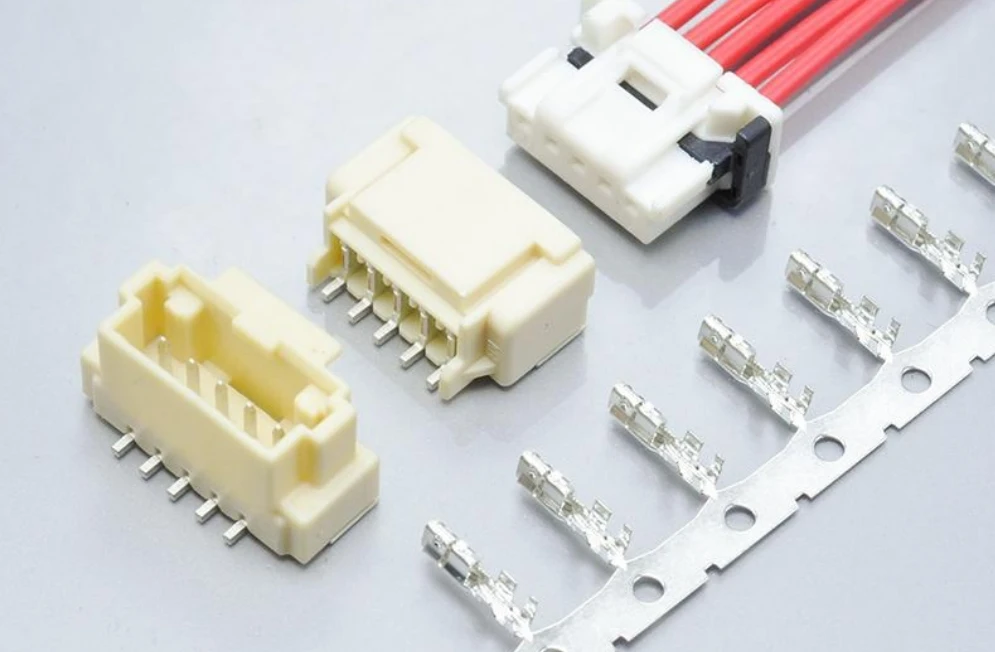

Terminal Components and Slice Display

Overview of Terminal Appearance and Slice Standards

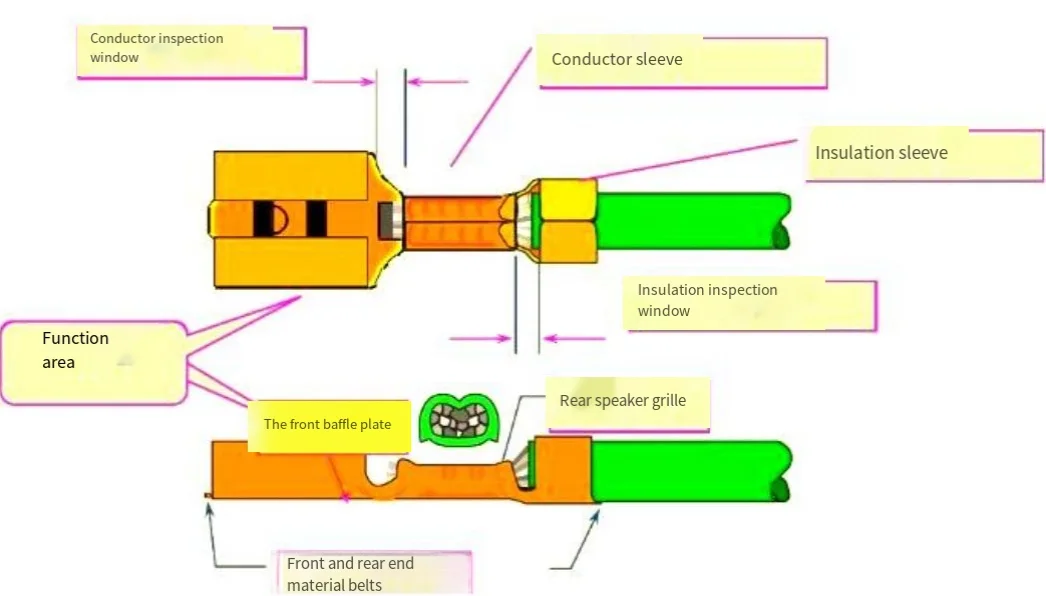

With every detail reflecting the precision of its functionality and ease of use, its design is compact and sophisticated: the terminal’s appearance and slice standards showcase its structural performance. We further examine the various components of the terminal following the discussion on the impact of core wire damage or cutting on electrical conductivity and mechanical strength.

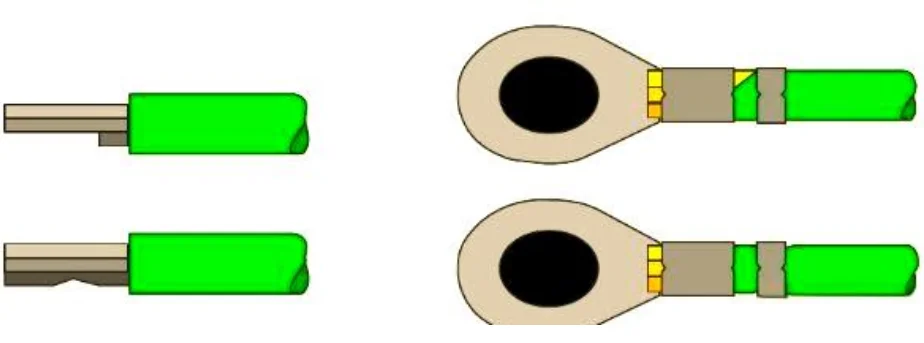

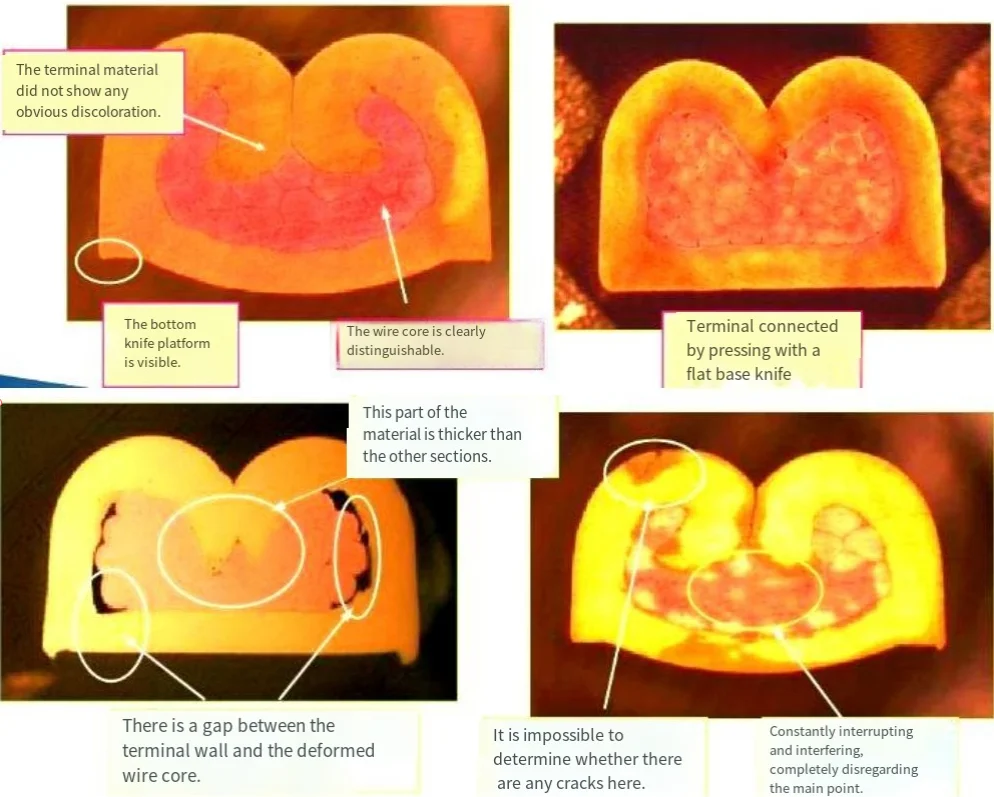

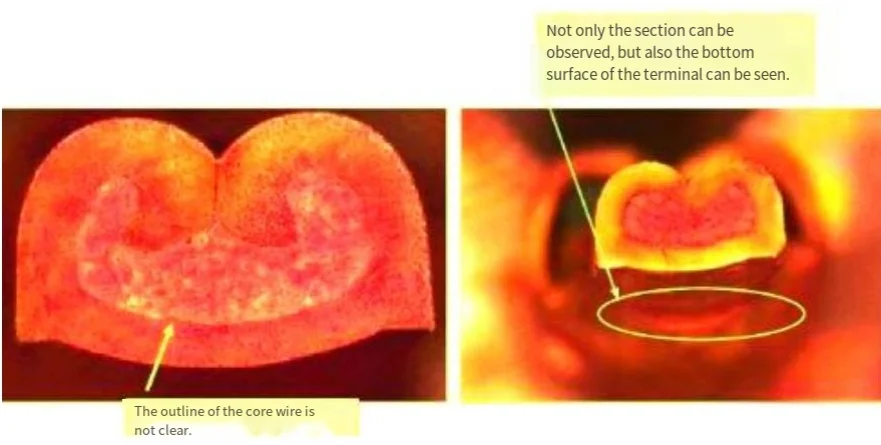

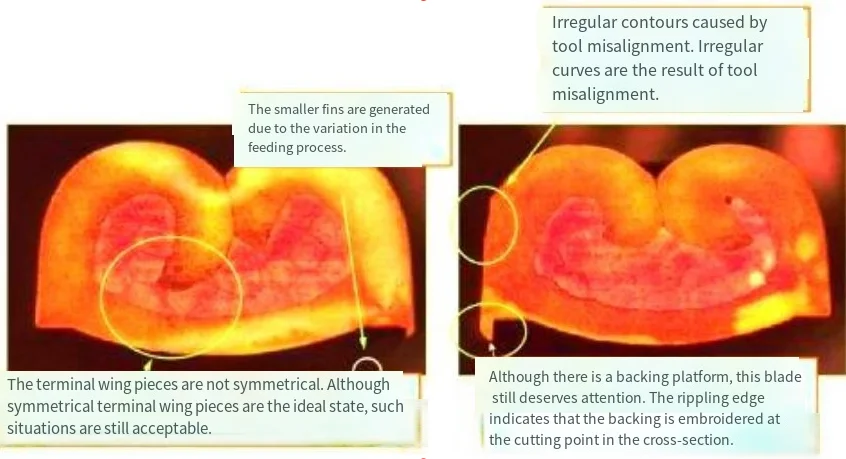

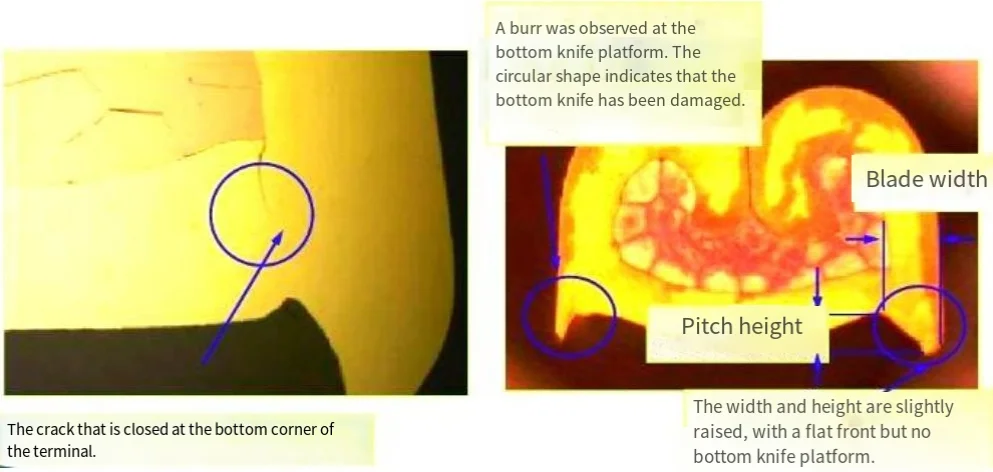

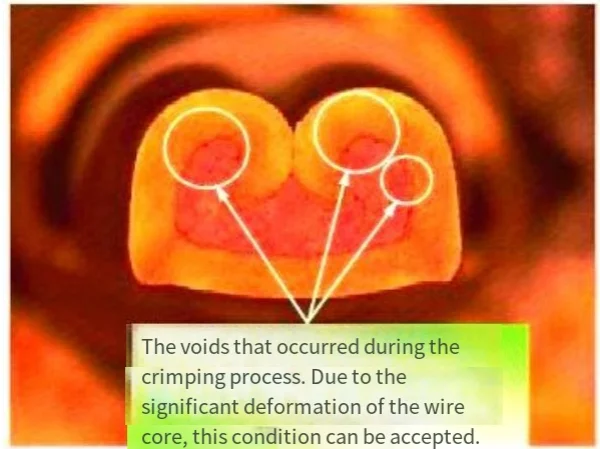

Display of Standard and Defective Slices

Details that can affect the accurate assessment of the terminal’s performance and quality include the absence of the presence of impurities or uneven coloration in the terminal material and the absence of a clear honeycomb-shaped deformation contour of the core wire, which are often observed in defective slices. These details are crucial for evaluating the terminal’s performance and quality, such as the non-mottled material of the terminal and honeycomb-shaped deformation contour of the core wire and the pure, which can be clearly observed through standard slicing techniques.

Measurement and Application of Intelligent Devices

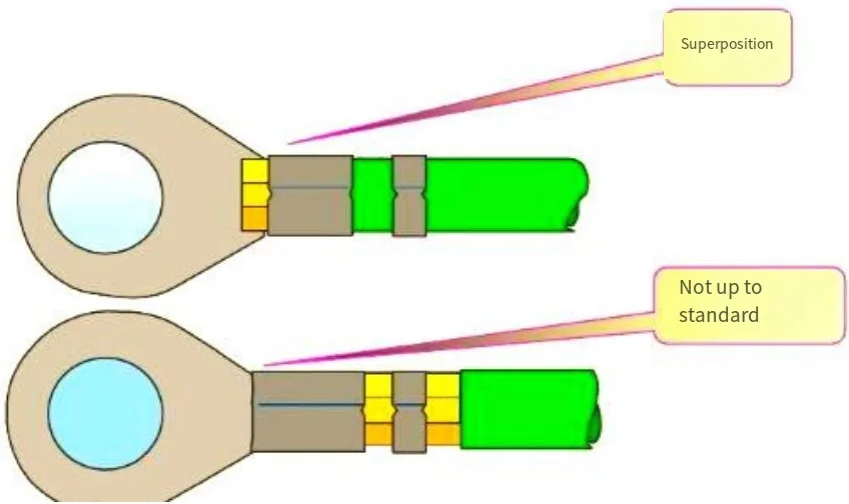

Conditionally Acceptable Slices and Measurement Methods

In certain cases, slices with minor imperfections may still be considered acceptable. For preliminary evaluations of terminal performance and quality, the terminal sections they reveal are sufficiently clear although these conditionally acceptable slices may not be flawless. However, it should be emphasized that even slices deemed acceptable may not fully comply with ideal quality standards, and therefore require cautious use.

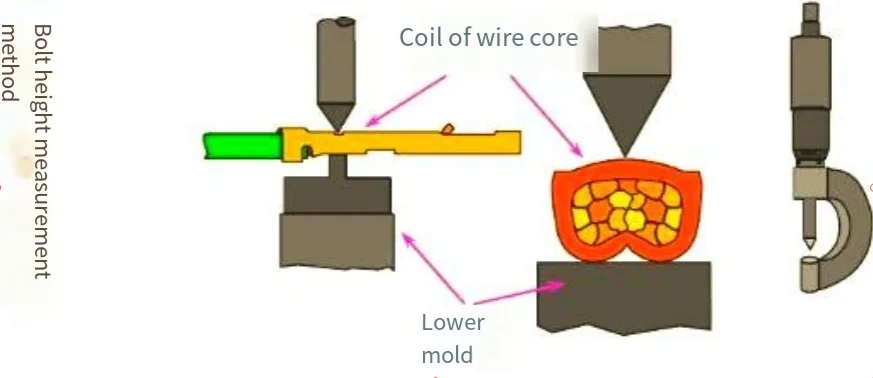

Application of Intelligent Tensile Testing Machine

The intelligent tensile testing machine can not only conduct professional tensile tests but also measure the crimping height. This offers all-round data support for evaluating conditionally acceptable slices.

Continue Reading

How to Analysis Terminal Material and Welding Process?

Electrical Terminal Materials: 4 Key Points (+How to Select?)

How Many Types of Electrical Terminals and Connector?(Guide for 14 Types)

How many types of connector and terminal insulation materials(3 major categories)

What factors determine the cost of electrical terminals and connectors? (10 Key Factors)

What Certifications Do Terminals and Connectors Need? (6 Common Types)