Definition and Function of Copper Connecting Terminals

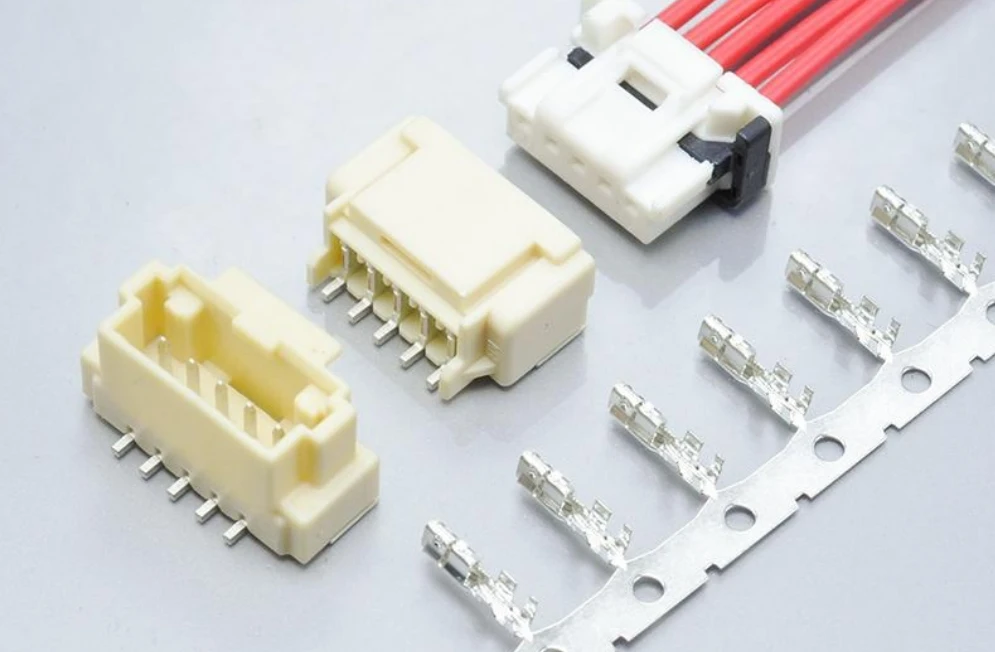

With good electrical conductivity and wear resistance, copper enables copper connecting terminals high durability and electrical performance. Copper connecting terminal blocks are accessories used for connecting wires, typically made of pure copper material.

Different types of copper connecting terminals are designed with various shapes and structures to meet different application scenarios and requirements. The function of copper connecting terminals is to connect wires, linking wires with equipment, terminal boards, or other devices to transmit electrical signals and power.

How to Select Suitable Copper Connecting Terminal Connectors?

Choose Appropriate Models and Specifications of Copper Connecting Terminal Blocks

Different specifications of copper connecting terminals should be chosen based on the cross-sectional area and purpose of the wires to ensure reliable and secure connections. Selecting appropriate models and specifications of copper connecting terminals is crucial to ensure connection stability and safety.

Confirm Terminal Shape and Structure

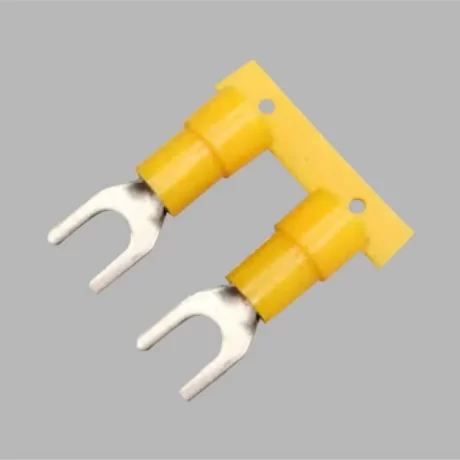

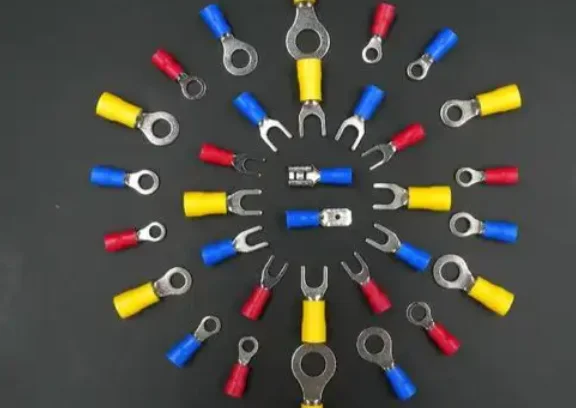

The suitable terminal shape and structure should be selected according to requirements to ensure optimal connection performance. Copper connecting terminals are available in various shapes and structures such as U-shaped, clamp-shaped, and tubular.

Confirm the Terminal Installation Method

Copper connecting terminals have various installation methods, including welding, crimping, screw-type. To ensure the stability and durability of the connection, the appropriate terminal installation method should be selected according to different application scenarios.

Precautions When We Choose Copper Terminals and Connectors

With excellent electrical conductivity and corrosion resistance, thickened copper tube terminals are widely used in various projects in the field of electrical connections. However, the quality of products on the market varies. The following key points should be noted when selecting high-quality products.

Confirm Compatibility Between Terminals and Wires

In order to ensure the stability and reliability of the connection, we should select copper connecting terminal blocks that are compatible with the wires used. This is because different types of wires are suitable for different types of copper connecting terminals.

Proper Terminal Installation

According to different installation methods and connection requirements, we should select appropriate devices and tools for proper terminal installation. This is because the stability of the connection can be ensured by proper installation of copper connecting terminals.

Avoid Using Inferior Copper Connecting Terminals

It is essential to choose reliable brands and products when selecting copper connecting terminal blocks. Inferior copper connecting terminal are easy to rust or deformation. As it is of low quality, it will lead to potential damage and unreliable connections to equipment.

Avoid Overloading

The appropriate specifications and models must be chosen according to different loads when selecting copper connecting terminals. Overloading will damage copper connecting terminals and wires. It will cause equipment failure or safety accidents such as fires potentially.

Pay Attention to Copper Purity

Copper purity directly affects the conductivity of terminals. We can verify if the copper content meets standards when purchasing. To verify it, we can request the supplier to provide a material report. Higher purity results in better electrical conductivity and lower resistance. We can inspect the terminal surface. Variegated or Dull surfaces may indicate impure copper. For high-quality copper, it will have a uniform purplish-red color. For genuine thickened copper tube terminals, the copper content usually exceeds 99%.

Confirm Dimensions and Specifications

Different electrical connection scenarios require specific terminal dimensions. Before purchasing, we can select compatible terminal specifications by accurately measuring parameters such as wire diameter and connection space. An undersized terminal could damage the wire or may not fit properly. An oversized terminal may impair conductivity and lead to lose connections.

Evaluate Process Quality

Silver plating further improves conductivity while Tin plating enhances the terminal’s oxidation resistance. Attention should also be paid to the terminal’s plating process, with common options including tin plating and silver plating. High-quality thickened copper tube terminals feature a uniformly thick tube wall. Smooth in surface without burrs, cracks, or other defects, they are formed using cold-pressing technology.

Choose Formal Channels and Brands

We suggest that customers prioritize well-known brands through formal distributors when buying products. Because their production processes strictly adhere to industry standards and they have better after-sales services and ensure better quality. Customers can understand the actual performance of the products by checking the brand’s reputation and user reviews.

Copper connecting terminals are indispensable accessories for ensuring the stability and safety of wire connections. To effectively prevent connection failures and safety accidents, we need to properly select and install. To ensure the stability and durability of connections, we need to pay attention to factors such as usage conditions, installation methods and terminal quality. It is essential to choose suitable copper connecting terminals according to different needs and application scenarios. Additionally, it is necessary to purchase multiple samples for practical testing. For example, we should check connection firmness and conductivity. By doing these checks, we can ensure that the products meet requirements.

Continue Reading

Tinned Copper Terminals VS Bare Copper Terminals: How to Choose? (8 Points to Consider)

Electrical Terminal Materials: 4 Key Points (+How to Select?)