Solderless Electrical Terminals and Connectors

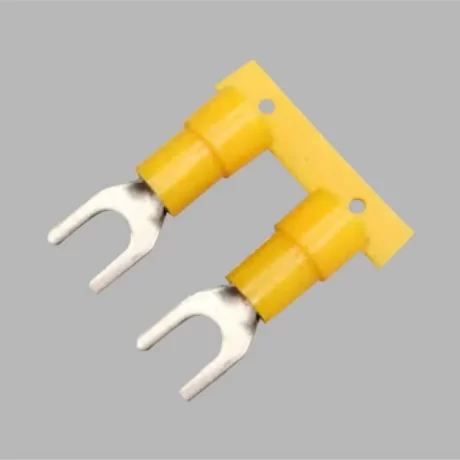

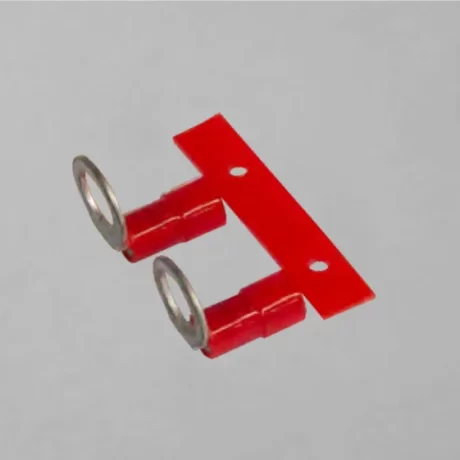

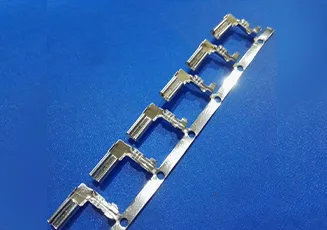

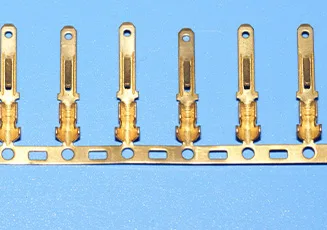

The solderless electrical terminal and connector is a device used to connect two or more electrical conductors without the use of solder. Due to this fact, they are faster and easy to assemble compared to the conventional soldered connections. Solderless terminals can be found in many wiring applications, ranging from automotive, aerospace to household electronics. Crimp terminals, push-in connectors, and terminal blocks are some of the forms they come in, depending on the application.

Their most important purpose is to ensure a reliable electrical connection while saving time during installation. Since they do not require solder, they decrease the associated risks of heat damage to components or wires. Besides, solderless electrical connectors are sometimes disconnectable and reusable, which makes them more convenient.

Solderless Terminal and Connector Products

-

$10Original price was: $10.$9Current price is: $9. -

$10Original price was: $10.$9Current price is: $9.

Related Terminals

Solderless Terminal and Connector FAQs

How does a solderless terminal differ in functionality from a solderless electrical connector?

What are the advantages of the use of solderless electrical terminals for automotive wiring?

Among the benefits which solderless electrical terminals make possible in automotive wiring are:

- Speed and Efficiency: Solderless terminals save time in installation compared to soldering. This fact becomes important in high-volume manufacturing and repair contexts within the automotive industries.

- Less Risk of Damage from Heat: Since most of the solderless terminals do not involve much heat, there is no further damage to heat-sensitive components. This becomes quite crucial when modern vehicle electronic systems are concerned.

- Resistance to Vibration: Most solderless electrical terminals are designed for high-vibrational environments; thus, they can be exceptionally applied in automotive due to the constant motion faced by exposed wiring.

- Ease of Maintenance: Very often, solderless terminals can easily be disconnected and then reconnected, hence ideal for wiring systems that would call for maintenance or upgrading from time to time.

Solder-less electrical terminals save time and reduce the complexity experienced during the set-up or repair of an automotive electrical system, hence is used in ensuring reliabilities in vehicles.

How do I choose the proper solderless terminal connectors for my electrical project?

The type of solderless terminal connectors that would be selected will depend on a few factors unique to your project:

- Wire Gauge: Make sure the terminal connector being used is compatible with the wire gauge – thickness – you have. If a connector bigger or too small than your wire is used, the result may be either bad connections or complete failures.

- Type of Connection: Classify whether you want a permanent or temporary connection. Crimp terminals are usually used for permanent applications, whereas quick disconnects serve better in the context of temperature applications.

- Environmental Factors: Type will be determined by the environmental factors that may be exposed to your project-meaning moisture, heat, and other factors. For example, nylon-insulated or heat-shrink terminals will add increased durability and protection.

- Electrical Load: Ensure your terminal connector falls within your application’s specified rating of current and voltage. Overrunning this capacity can lead to overheating or electrical failure.

Through the comparison of all these factors, you can select a solderless terminal connector to meet your requirements for an electrical project and fulfill your needs related to both performance and safety.

Is it possible to use solderless terminals in highly vibrated industrial machinery?

What are solderless electric connectors made of, and for what reason is each material important?

How do I properly install solderless terminal connectors so that the electrical connection is secure?

The following procedure will help make secure electrical connection using solderless terminal connectors:

- Alternative Connector: Choose a terminal connector depending on the wire gauge required and the connection type.

- Strip Wire: Remove the insulation from the wire, exposing adequate conductor to enter the terminal without leaving any of the wire beyond the connector.

- Insert the Wire: The wire is then inserted inside the connector barrel with all strands inside the connector and not frayed.

- Crimp the Connector: Using a crimping tool intended for the type of terminal being used, be sure to apply the correct pressure for a tight connection.

- Check the Connection: Lightly tag the wire to ensure the crimp is in place. If it moves, you may have to retry the crimp or check that you are using the right-sized terminal.

Proper installation means a reliable, long-lasting connection that will not fail when subjected to normal operating conditions.

What are standard sizes and specification available in solderless terminals and connectors?

Is it possible to use solderless electric connectors for high-current applications, and what is the limitation of their use?

In what respect do solderless electric terminals help in reducing time and cost of installation?

Solderless electrical terminals reduce installation time and cost by a number of means, including:

- No Soldering: The installation is faster without soldering and requires even less specialized labor.

- Reusable Connectors: Due to the design nature of some solderless terminals, they can be disconnected and reused at any time, hence reducing material costs in those multiple instances when changes need to be made to connections.

- Tool-Free Installation: Most solderless terminals, such as of the push-in type, do not make use of any tools, which again is a reduction of time and easing in installation.

On the whole, these terminals make the installation process simpler and, for that reason, cost-effective in huge electrical projects involving the likes of automotive, construction, and electronics industries.

Connect Our Team

Address: No.3, 168 Industrial Zone, Xincun Street, Tangxia Town, Dongguan City, Guangdong Province, China

Applications

- Wire Terminals

- LED Terminals

- Auto Terminals

- Battery Terminals

Services

Get Answers Now