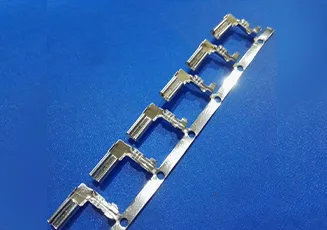

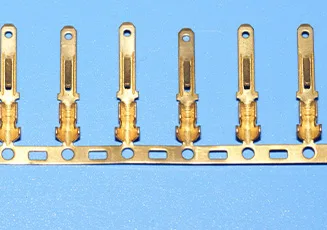

Female Male Terminals

Femal Male Terminal and Connector Products

-

$10Original price was: $10.$9Current price is: $9.

Related Terminals

Male and Femal Terminal and Connector FAQs

What are the main distinctions between male and female connectors?

Male and female terminals have wide applications in different practical settings:

- Auto Wiring: The terminals are widely used in vehicles where male and female terminals link elements such as lights, sensors, and engine components. They enable easy disconnection and reconnection of parts for repairs or replacements.

- Industrial Machinery: Male and female terminals are also commonly applied in industrial equipment to achieve the connection of motors, sensors, and control panels. Their powerful construction guarantees their secure connection can be remained in conditions with vibration and mechanical stress.

- Consumer Electronic Device: Male and female terminals are applied in devices like computers, televisions, and audio equipment to transmit power, video, and audio signal. USB, HDMI, and power plugs are typical examples of male-female connections in daily electronics.

- Household Appliance: In home appliances like refrigerators, washing machines, and dishwashers, male and female terminals are applied for different internal components connection, which provides a reliable and safe connection that can be easily functioned.

- Solar Power System: Male and female electrical terminals have widespread application in the setup of solar panel to connect panels to inverters and battery systems. Their weatherproof design guarantees long-term reliability in outdoor applications.

What important roles does a male female terminals play in auto settings?

Male female terminals play a crucial role in auto applications for multiple reasons:

- Ease of Maintenance: Male and female terminals achieve fast disconnection and reconnection of wiring harnesses, sensors, and lighting elements, which simplifies maintenance and repairs.

- Vibration Resistance: Auto settings are subject to continuous motion and vibration. Male and female terminals are built to offer secure and vibration-resistant connections that keep reliable even under harsh conditions.

- Weatherproofing: Lots of automotive terminals are designed with seals or are crafted with weatherproof materials, which protects the connections against moisture, dirt, and other environmental conditions.

- Modularity: Male and female terminals used in auto wiring enable the easy integration of new elements like sensors or lighting systems, with no extensive rewiring.

What are the commonly used kinds of male female terminals in practical applications?

Different kinds of male female electrical terminals are applied for different industries:

- Bullet terminals: A male bullet-shaped terminal that fits into a female socket is contained in these terminals. They are usually applied in auto wiring and motorcycle electrical systems where fast connections are required.

- Pin & Socket Connectors: This type of terminals that features male pins that insert into female sockets is frequently found in industrial control systems and auto wiring harnesses, where a tight and secure connection is ensured.

- USB terminals: These terminals that plug into female sockets on laptops, and peripherals are employed in consumer electronic products, which provides data transfer and electricity.

- Power terminals: Male and female power terminals are applied in devices like household appliances, power tools, and medical equipment where electrical power sources are connected to devices in a safe and reliable manner.

- Coaxial terminals: These terminals, applied in television and radio systems, contain a male connector with a central pin that plugs into a female terminals to transfer signals.

- Circular Connectors: Circular male and female terminals have applications in military, aerospace, and industrial machinery settings, where rugged, reliable, and waterproof connections are necessary.

How is the safety of electrical systems guaranteed by male female connectors?

Male and female electrical connectors are essential in ensuring safety in electrical systems by:

- Secure Connections: The design of male and female connectors guarantees a tight match that decreases the risk of accidental disconnections, which could result in short circuits or electrical faults.

- Polarization: Lots of male female connectors are built to be polarized, which means they can only be connected in one direction. This avoids wrong wiring that could lead to damages or pose safety hazards.

- Weather Resistance: In outdoor or auto settings, lots of male and female connectors are equipped with seals or made from weatherproof materials that protect the connection against water, dust, and corrosion.

- Insulation: The insulation on male and female connectors prevents users against accidental contact with live electrical components, which reduces the hazard of electrical shock.

What are the benefits of applying male female connectors in industrial devices?

In industrial equipment, male and female electrical connectors offer multiple crucial profits:

- Durability: These connectors are constructed to endure extreme environments, which include exposure to dust, chemical substances, and mechanical stress. Their powerful construction guarantees they remain functioning in high-demanding settings.

- Modularity: Industrial systems can be easily modified or expanded using male and female connectors. New elements like motors, sensors, or control modules can be added with no rewiring of the whole system.

- Ease of Maintenance: Quick-disconnect features in male and female connectors allow maintenance teams to fastly replace or function individual components with no need of taking the entire system offline.

- Vibration Resistance: Industrial machinery usually runs in high-vibration settings, and male and female connectors are built to withstand loosening or damage led by vibration.

How can the wiring in solar power systems be simplified by male female terminals?

Male and female electrical terminals are essential in solar power systems for several reasons:

- Quick Setup: These terminals allow it to easily connect solar panels to inverters and battery systems, which speeds up the setup process and ensures secure, reliable connections.

- Weather Resistance: Solar setups are usually exposed to the components. Male and female terminals applied in solar systems are crafted to ensure high temperatures, UV rays, moisture, and dirt, which ensures long-term reliability.

- Easy Maintenance: If a part of the solar system needs replacement or upgrade, male and female terminals enable fast disconnection and reconnection, which reduces system downtime.

- Modular Design: Solar systems can be easily expanded by male and female terminals. Extra panels can be connected to the current installation with no need to repair the core wiring system.

What are the crucial considerations for the selection of male and female connectors for outdoor settings?

Regarding the selection of male and female connectors for outdoor settings, it’s crucial to take the following factors into consideration:

- Weather-Resistant: Connectors that are specifically crafted for outdoor use and have weather-resistant ratings (like IP-graded connectors) should be chosen to give protection from rain, dust, and other environmental conditions.

- UV Resistance: For connectors that have exposure to sunlight, such as in solar power systems, they should be ensure that they are made from UV-proof materials to avoid degradation as time goes by.

- Temperature-Proofing: Connectors that can handle harsh temperatures should be chosen, particularly if they need to be applied in environments with significant temperature variations (such as hot, desert climates or cold, snowy areas).

- Durability: Outdoor connectors are built to be durable enough to protect against physical wear and tear. Connectors with powerful housings, locking mechanisms, and corrosion-proof materials should be selected for extended outdoor applications.

What are the applications of male connectors in data transfer systems?

The main difference between male and female connectors lies in their design:

- Male Connector: They contain protruding pins or prongs that insert into the female connector. These connectors are usually employed in plugs or ends of cables, allowing them to easily connect to power sources or other appliances.

- Female Connector: Female connectors include recessed sockets or holes built to get the male connector’s pins. They are universally applied in ports or appliances to offer a secure point of connection.

In practical terms, male connectors are typically discovered on cables, while female connectors can be found on devices or equipment plugged by cables.

How are male female electrical connectors applied in consumer electronic products?

In consumer electronic products, male and female connectors are applied for a wide range of settings, which includes:

- Power Supply Connection: male connectors on power cords are utilized in devices like computers, mobile phones, and gaming consoles and female connectors on devices to achieve the secure delivery of electrical power.

- Data Transfer: USB connectors, HDMI connectors, and audio jacks are typical examples of male and female connectors applied in laptoprs, televisions, speakers, and other electronic devices to transmit data and audio/video signals.

- Charging Devices: Male connectors on chargers are applied to link with female charging ports on appliances like smartphones and tablets, which ensures efficient and safe electricity transmission.

Why are male female terminals crucial in medical devices?

Male female electrical terminals play an essential role in medical devices for multiple reasons:

- Safety: Precise and secure connections are required by medical to guarantee the safe delivery of electricity and data. Male and female terminals are built to be fool-resistant, which reduces the risk of improper connections that could hurt patients.

- Sterility & Durability: terminals rated for medical environments can endure sterilization and frequent operation. Lots of male and female terminals are built to be durable and easy for maintenance.

- Modularity: Medical devices usually require to be updated or functioned. Male and female terminals enable elements such as sensors, monitors, or probes to be easily swapped out with no disturb of the whole system.

- Reliability: In important medical devices like ventilators, monitors, and infusion pumps, male and female terminals offer the reliability required for constant operation in life-saving equipment.

How is the aerospace industry benefited from male female connectors?

In aerospace settings, male and female electrical connectors offer multiple profits:

- High Reliability: Connectors required for aerospace systems can function well under harsh conditions, which includes high altitudes, temperature variations, and mechanical stress. Male and female connectors built for aerospace settings offer high reliability in these high demanding conditions.

- Superlight & Compact: Aerospace systems require elements that are lightweight and space-saving. Male and female connectors applied in aerospace settings are usually built to be space-efficient, which ensures they can be used in tight spaces with no addition of unneeded weight.

- Quick Disconnection: In aerospace maintenance and repairs, male and female connectors enable technicians to swiftly disconnect and reconnect elements, which guarantees minimal downtime during critical operations.

- Resistance to Vibration and Shock: Aircraft and spacecraft are subjected to intense vibration and shock when operating. Male and female connectors applied in the systems are constructed to resist loosening or damage, which ensures the constant functioning of crucial elements such as avionics, sensors, and electricity systems.

What are the best practices for the application of male and female connectors in extreme conditions?

When male and female electrical connectors are applied in harsh conditions, the best practices are listed as follows:

- Weather-Resistant or Sealed Connectors: For outdoor or moisture-prone conditions, connectors used are built to handle moisture, dust, and harsh temperatures like those with built-in seals or weather-resistant ratings.

- Heat-Proof Materials: In high-temperature conditions like in auto engines or industrial furnaces, connectors made from heat-resistant materials should be selected to avoid degradation over time.

- Use Dielectric Grease: In marine or outdoor settings, dielectric grease to the connection should be used because it is helpful for protecting it against corrosion led by moisture or saltwater.

- Periodical Inspection & Maintenance: For systems in extreme environments, periodical check and cleaning of male and female connectors are helpful for identifying wear, corrosion, or other problems before they cause electrical faults.

Can male and female electrical connectors be recycled?

Yes, male and female electrical connectors can typically be reused if they stay in good condition and have not exposed to any damage or compromise. Practical cases of reusable connectors contain:

- Auto Wiring: Male and female connectors in auto applications, such as bullet connectors or quick-disconnect terminals, are usually reused when repairing or replacing parts.

- Consumer Electronics: Connectors like USB, HDMI, and electricity plugs can be connected and disconnected many times with no loss of performance, which make them reusable for different devices.

- Industrial Machinery: In control systems and wiring, male and female connectors can achieve frequent disconnection for maintenance or upgrades and reconnection when necessary.

However, it’s crucial to periodically check the connectors for any signs of wear, corrosion, or damage. If the contacts or insulation are worn, replacement should be conducted to guarantee reliable and safe connections.

How does a male female electrical connector function in high-current settings?

Male and female electrical connectors can be applied in high-current settings when rightly rated for the electrical load. In these circumstances, connectors are especially built to withstand high amperage with no overheating or degradation. Instances of practical uses contain:

- Auto Battery Connection: Male and female connectors graded for high-current loads are applied to connect car batteries and other high-electricity systems, which ensures reliable energy transmission and minimizes voltage loss.

- Industrial Power Division: Heavily-used male and female connectors are applied in industrial systems to connect machinery and divide power efficiently across high-current circuits.

- Solar Power System: High-current male and female connectors are employed in solar panel arrays to connect inverters and batteries, which guarantees safe and efficient power transmission.

For these application settings, it’s essential to choose connectors specifically built for the current they carry to avoid issues like overheating or electrical failures.

Connect Our Team

Address: No.3, 168 Industrial Zone, Xincun Street, Tangxia Town, Dongguan City, Guangdong Province, China

Applications

- Wire Terminals

- LED Terminals

- Auto Terminals

- Battery Terminals

Services

Get Answers Now