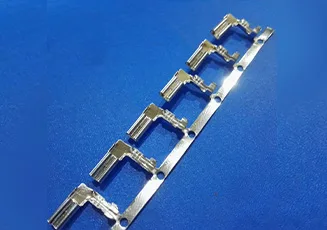

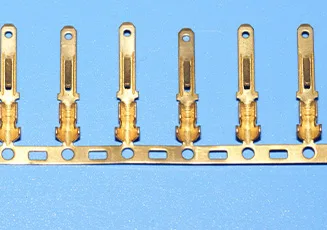

Round Terminals

Circular terminals, also known as ring terminals or copper noses, are a commonly used electrical connecting device with the following characteristics:

Shape design: usually cylindrical, made of metal material with good electrical conductivity.

Internal structure: There is a threaded structure inside, which can firmly fix the

Round Terminal Products

-

$9Original price was: $9.$8Current price is: $8.

Related Terminal Connectors

Round Terminal and Connector FAQs

What advantage does working with round terminals offer?

- Versatility: Round terminals can accommodate a wide range of wire gauge voltages and bolt sizes.

- Reliability: Due to their circular shape, they provide a powerful mechanical connection.

- Ease of installation: Round terminals are rather simple to install, requiring only crimping tools and a screwdriver.

- Durability: Round terminals installed properly will withstand any vibrations and harsh environmental conditions.

How Many special types of round terminals?

Team members of the Wire Harness Department are trained in accordance to meet these rigorous standards. This includes instituting strict process controls for monitoring soldering stripping, crimping, securing, etc.

How to install a round terminal?

Usually, to install a round terminal, you’ll require:

- Wire strippers: These strip the wire insulation.

- Crimping tool: Used to crimp the terminal onto the wire.

- Round terminal: Chosen for your particular application.

- Bolt or stud: Used to keep the terminal in place.

Strip the insulation from the wire. Insert the wire into the barrel of the terminal and crimp the terminal onto the wire using a crimping tool. Finally, place the terminal ring over the bolt or stud and tighten a nut to secure it in place.

Can I reuse a round terminal?

How is a ring terminal different from a lug?

How do I create a complete bond with a round terminal?

Recommendations for establishing a solid connection using round terminals include the following:

- Select the appropriate size: Choose a terminal that suits the wire gauge and has a bolt diameter.

- Crimp with strength: Use a crimping tool to develop a well-formed mechanical connection between the terminal and the wire.

- Tighten the nut: Ensure that the nut is tightened sufficiently so as not to loosen or disengage the terminal.

- Examine for external damage: Before installing the terminal, inspect it properly for cracks, burrs, and suchlike.

What are the common applications of round terminals within automotive wiring?

Are round terminals able to be used in marine applications?

What is the function of insulation in a round terminal?

Can I use a round terminal with stranded wire?

What is a round terminal?

Connect Our Team

Address: No.3, 168 Industrial Zone, Xincun Street, Tangxia Town, Dongguan City, Guangdong Province, China

Applications

- Wire Terminals

- LED Terminals

- Auto Terminals

- Battery Terminals

Services

Get Answers Now

- About Us

- Faqs

- Privacy Policy